Advancements in 3D Injection Molding

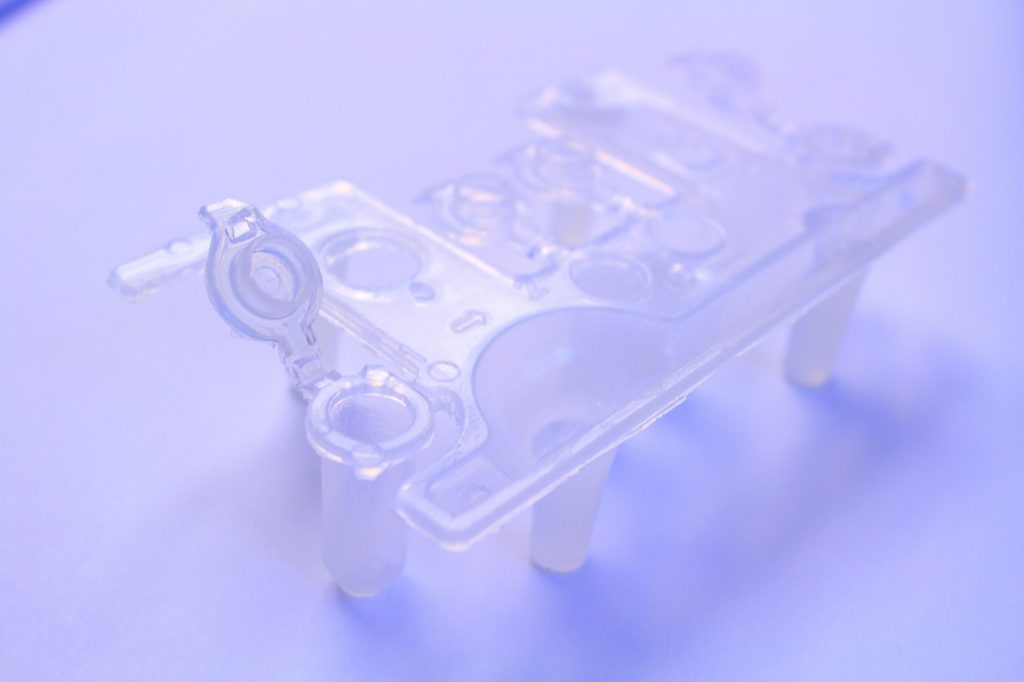

The level of quality that is attainable with parts molded from 3D printed molds continues to improve. From the beginning, we knew the actual production resins would be available and that iteration cycles would happen more quickly. Early questions focused on surface finish, achievable tolerances, and the number of shots a 3D Injection Mold (3DIM) could produce. Thanks in part to testing by the Natech Engineers, the technology is starting to show gains in all three areas.

Surface Finish

Anyone who has held a 3D-printed model is familiar with the ridged layers along the surfaces which are formed by the 3D-printing process. Since the 3DIM inserts are produced layer by layer, they exhibit this rough surface finish as well. This texture is in turn transferred to the molded parts, which presents a drawback when prototype testing requires a high-level surface finish.

If we look at surface finish as a microscopic view of the various peaks and valleys of the surface profile, we can generally categorize surface finish enhancements as either adding or removing material from the base 3DIM insert. The additive approach fills in the valleys with various coating and/or plating techniques. The subtractive approach removes the peaks with polishing, sanding, and/or burning techniques.

The Natech engineers ran a number of experiments along both tracks and with some additional post-processing of the inserts was able to achieve an SPI C-level finish. This finish achieves a variety of functional wins for our clients, including a tight seal in a closure feature, improved aesthetics, and optical translucence.

Tolerances

The tolerances that may be held will greatly depend upon the part geometries. Generally a dimension that is below 0.500” would have a standard tolerance of +/- 0.005”. A generic 1.5” feature could reasonably hold +/- 0.010” tolerances. As the dimensions increase, the tolerances also increase. Poor surface finish, fill progression, ejection, and cooling can also adversely impact the tolerances that can be held.

After achieving smoother finishes and experimenting with processing, the Natech engineers collected and analyzed data on the tolerances held. Although the data is limited so far to the specific applications tested, the results so far show that standard tolerance can be held. Features above 0.500” were still holding tolerances below 0.005”. This is achieved because the parts were produced by the injection molding process in the actual production material.

Molding Cycles

The number of cycles a single set of mold inserts could reach was originally described as dozens. After this, the wear caused by the compression forces would start to interfere with the parts. In tests with non-abrasive materials, such as PP or ABS, a single set of inserts has produced several hundred parts. Now the lifetime of an insert set could be described as less than a thousand.

A common need so far for insert replacement has been flash. Flash development must be considered relative to the impact on the prototyping objectives as well as the economics involved with flash removal. At some point, moving to the next iteration is the sound choice. Trimming flash on a handful of parts is very different from trimming flash on hundreds of parts.

Conclusions

As with any nascent technology, 3DIM continues to show improvements as the technology is tested with real-world applications. As quality improves, the usefulness expands. As lead times decrease and life cycles increase, prices would then come down as well. More time will bring more experiments and more knowledge about the uses and benefits of 3DIM added to the collective learning of the manufacturing community.