Design and Development

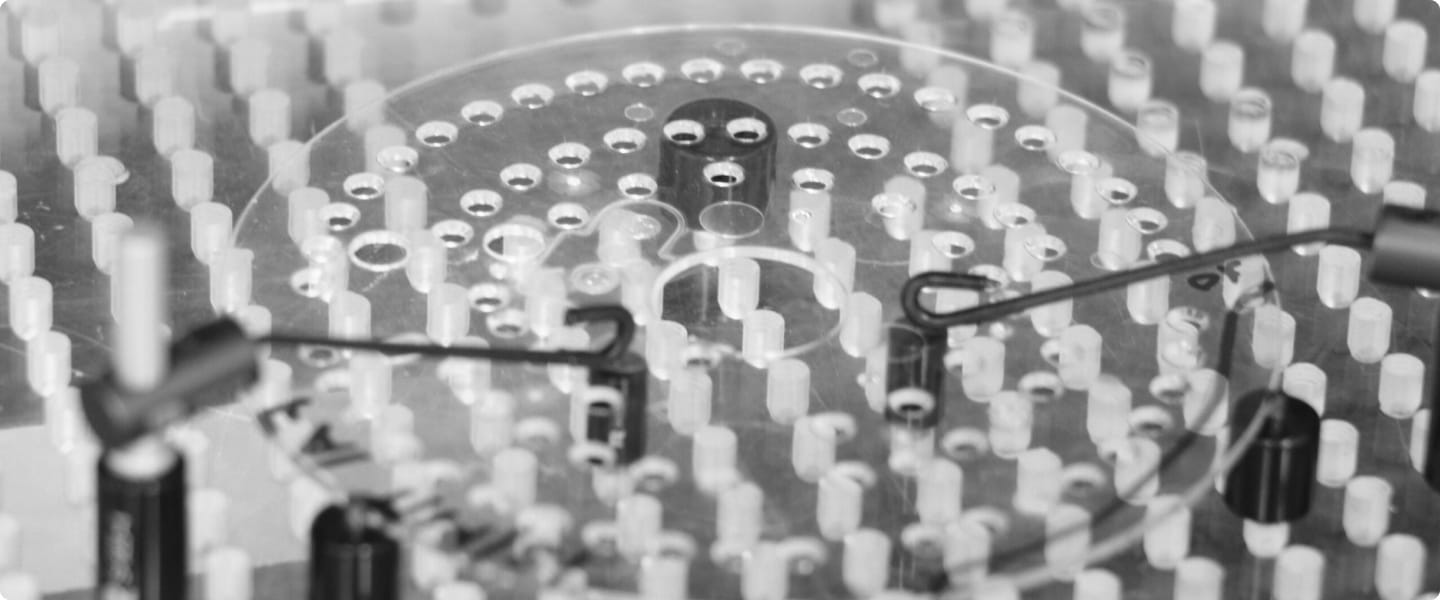

Optimizing your consumable for manufacturability, quality, and cost.

Scale your startup with contract manufacturing, injection molding, and engineering solutions of complex consumables and instruments.

Partnering with Natech means taking advantage of our global suite of design and manufacturing solutions.

Optimizing your consumable for manufacturability, quality, and cost.

Scaling complex assemblies, including laminate stack-ups, welding, filling and sealing, and finished devices.

As part of the STRATEC Group, we are the go-to partner for IVD and life sciences manufacturing. We support both the startup community and established companies by guiding your product from early prototypes through commercial production.

Covering all aspects of IVD and life science instrument development and manufacturing

Customized content filling and pre-loading of liquids and reagents

Developing custom software and IoT solutions under the highest cyber security standards

Manufacturing polymer consumables with small structures of 150nm

“They cultivated the relationship with our company and provided outstanding knowledge and support."

Michael D.President & Founder

“Natech has been a great partner to collaborate with in our journey of transitioning manufacturing capability from prototypes to low volume production and scale. We have benefited from Natech's experience with plastics as validation and standardizing the production process for our consumables."

Suresh N.Head of Platform Integration

“Natech has been a trusted partner with the injection molding of components, tool care and operational support so that we can focus on our core business of producing final products."

Frank F.Division President

“An awesome team, holistically! From the engineers, to managers, to Quality, and Process Engineers. And everyone in between. Professional, accurate, honest, fun to work with. I can't express enough how impressed everyone on my team has been with the Natech Team."

Tyler B.Product Design Engineer

“Natech has been a great partner from the beginning and still eight years later. Their customer service and engineering team are always available when needed, and they have been flexible with our products and design changes. As a customer that can be challenging, Natech is always up for the task to keep our products coming."

Jason C.Supply Chain Manager

Our manufacturing facilities across the United States and around the world offer one-of-a-kind, fully-integrated services for every aspect of your manufacturing needs.

Driven by Collaboration, Fueled by Continuous Improvement

Our long-standing expertise, quality processes, and collaborative spirit make us the ideal partner.