Top 3 Benefits of Using COC for Medical and Diagnostic Applications

Discover the Power of Optimal Clarity with COC Resin

In analyzing blood cells, tissues, or proteins, it’s imperative to utilize a resin that has exceptional optical clarity and transparency. That’s where COC comes in.

COC, also known as cyclic olefin copolymer, is the unrivaled choice for medical and diagnostics applications such as microfluidics, cuvettes, cartridges, and well plates. Its superior optical properties make it the go-to resin for achieving unparalleled accuracy and precision in product development. If you strive for excellence in your work, there is no better option than COC.

Let’s dive into the specific benefits of using COC for your diagnostics and medical products.

Top 3 Benefits of Using COC

Benefit 1: Optical Transparency

COC is known for its ability to achieve a wide range of light transmissibility and different wavelengths, including visible light, UV light, and infrared. The high transmissibility rate, along with low autofluorescence and birefringence, makes COC a top choice for applications that require high optical clarity.

Benefit 2: Great Mechanical Properties

COC is known for its high rigidity, durability, and strength. Additionally, it’s heat resistant, which means it can be sterilized through autoclaving. COC’s properties make it useful for applications that require parts that can withstand harsh conditions.

Benefit 3: Chemical Compatibility

COC is resistant to solvents like alcohol and biocompatible with test subjects like tissues and proteins. This makes it ideal for applications that require parts that can tolerate exposure to different chemicals.

Uses of COC in Medical and Diagnostics Products

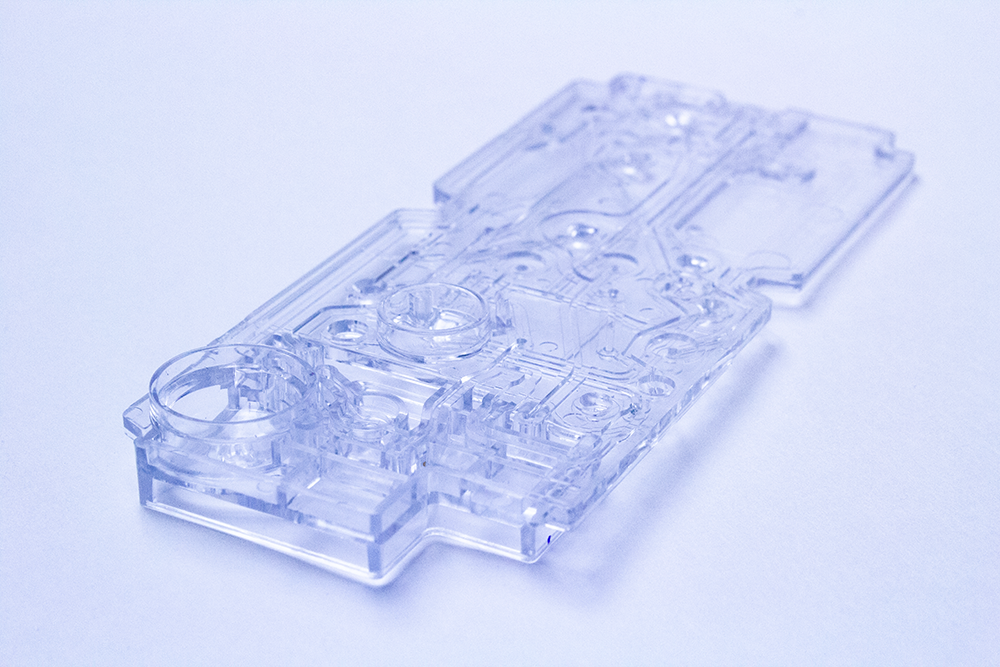

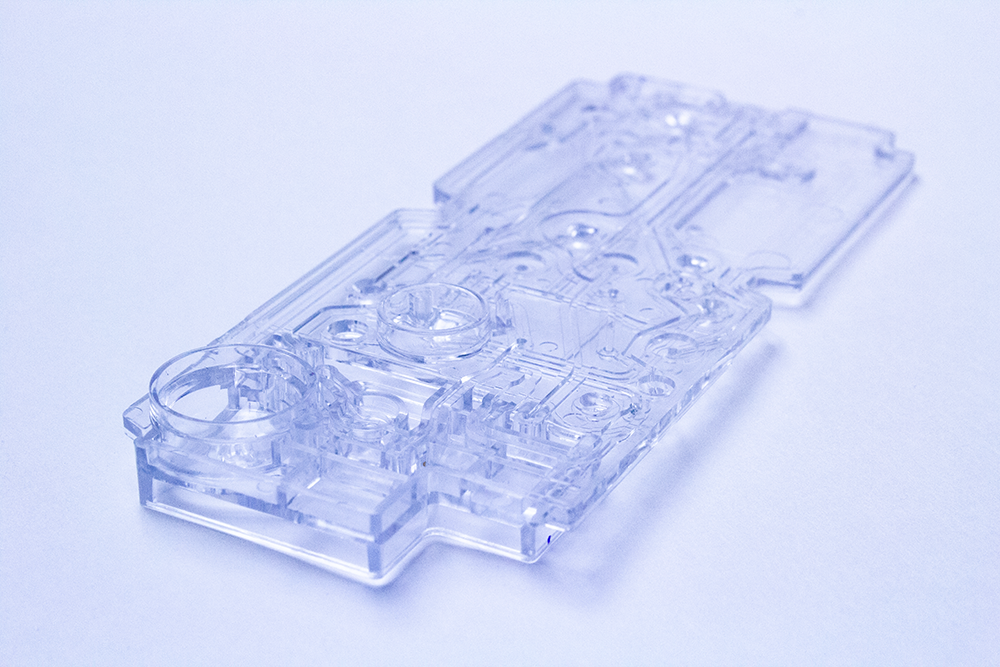

Microfluidics

One of the most exciting applications of COC resin is microfluidics. Microfluidics is a rapidly growing field that involves the manipulation of small amounts of fluids in extremely small channels. These channels

need to be optically clear or transparent and hold very fine tolerances to meet their functional requirements.

COC has several advantages when it comes to microfluidics. It’s an excellent choice for applications that require parts that are biocompatible and resistant to chemicals. COC is also very durable and can withstand high temperatures and temperature fluctuations.

At Natech, we use COC to manufacture microfluidic devices in large quantities. Our microfluidics experts have extensive experience in scaling up microfluidic processes to ensure our clients receive high-quality parts to meet their specifications.

Cartridges

Cartridges are another application where COC excels. COC is widely used for manufacturing cartridges for point-of-care diagnostic devices and drug delivery systems.

COC’s optical properties allow for accurate and precise measurement of fluids within the cartridges. Its low absorption and high transmittance ensure that the cartridge does not interfere with the sample or drug being analyzed or delivered. Additionally, COC has low particle generation, which is critical in maintaining the purity of the sample.

COC’s mechanical properties also make it an ideal material for manufacturing cartridges. Its high strength and dimensional stability allow for the production of cartridges with tight tolerances and small features. COC is also highly resistant to breakage, cracking, and deformation, which is great for applications that require durability and long-lasting performance.

Cuvettes

Cuvettes are commonly used in medical and diagnostic applications to measure light absorption, fluorescence, and turbidity. Because of its superior optical properties, COC is an excellent choice for manufacturing cuvettes. This makes it possible to achieve highly accurate, precise, and reliable measurements.

COC has a high transmissibility rate and low autofluorescence and birefringence, which are critical factors for cuvette applications. These properties ensure that the cuvette doesn’t interfere with the measurements. COC’s high optical clarity and transparency also allow the viewer to easily visualize the sample inside the cuvette.

In addition to optical properties, COC also has great mechanical properties. COC is highly resistant to stress cracking and has great dimensional stability, making it possible to manufacture cuvettes with high precision and tight tolerances. COC is also resistant to chemicals typically used in cuvette applications, which ensures the material’s durability over time.

Well Plates

COC is excellent for medical and diagnostic well plates used in assays like ELISA, PCR, and cell culture because of its high transparency and clarity, ensuring accurate results.

Well plates need to be durable and rigid to withstand the handling and manipulation during assay performance. COC is heat resistant, which means it can withstand high temperatures during the manufacturing process and sterilization through autoclaving.

COC is resistant to solvents like alcohol, which makes it ideal for assays that require the use of solvents. Additionally, COC is biocompatible with the tissues and proteins used in assays, which makes it a safe choice for medical and diagnostic applications.

Achieve Reliable and Precise Results

In summary, COC is an excellent choice for applications that require high optical clarity, such as well plates, cuvettes, and microfluidics. Choosing the right material for your medical and diagnostic applications and devices is critical to achieving accurate and reliable results.

When you’re ready to start developing your device, reach out to us. Our experts will help you solidify the material that’s best for your needs. Natech is here to help you make the best choices and scale up your device.