Design for Ejection

Design for Manufacturing – Plastic Part Ejection

“Design is how it works” according to Ken Kocienda’s book Creative Selection, where he describes his design process at Apple. Joseph Juran’s definition of Quality by Design incorporates the making, selling, buying, and using of the product. Sacrificing any one of these sacrifices the quality of the part. Design for Manufacturing describes the body of knowledge around the integration of product design and making.

I have seen clients who look like a deer caught in the headlights when they realize they need to consider design for manufacturing. They want to make their product as designed. The realities of manufacturing emerge and the solutions impact the part design.

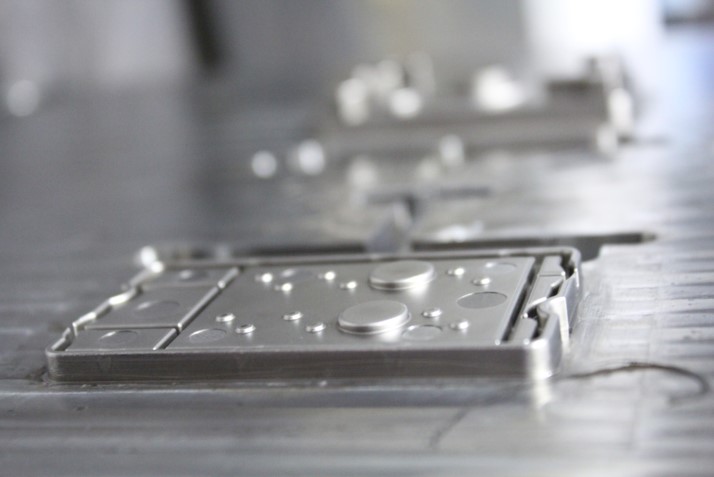

With injection molded plastics, you can think of design for making as a taxonomy with Design for Manufacturing at the top. Under that comes Design for Injection Molding. Injection molding comprises three phases: filling the mold with melted plastic, cooling the plastic into a hardened part, and ejecting the plastic part from the injection mold. With Design for Injection Molding we consider Design for Filling, Design for Cooling, and Design for Ejecting. We will delve more deeply into ejecting.

Why Design for Ejection?

This aspect of design for manufacturing reduces the risk that the part will get stuck in the injection mold or damage during ejection. As plastic cools, it shrinks around the core. As the injection mold opens, ejection features push the part from the mold.

Plastic parts or injection molds without a proper design for manufacturing can cause deformation, warpage, sticking, and drag marks. These impact part quality risk and cost risk.

How do I Design for Ejection?

To reduce these ejection risks, the engineer updates the design for manufacturing.

Remove Undercuts – Unnecessary undercuts can increase mold complexity and introduce quality risks.

Optimize Ribs – Excessive ribs increase sticking risk.

Add Draft Angles – Draft angles reduce the force required to eject the part from the mold.

Assign Surface Finishes – Polished finishes further ease the ejection of the part from the mold.

Define Ejection Types and Surfaces – Ejection features create ejection marks. Selecting the right type and location of marks should minimize risk.

What can go wrong with Design for Ejection?

Each design for manufacturing decision area brings tradeoffs. Solving one problem can create new problems so you want to make decisions with consideration of the full system. Some combination of decisions can optimize the overall risk mitigation.

You can watch this Design for Manufacturing video from your friendly neighborhood engineer about how increasing draft improved the ejection risk but created a non-fill risk at the end of a small leg. As a result, the engineer added a rib along the length of the leg to improve filling of the mold.

Conclusion

Design for manufacturing describes a process of identifying and reducing risks. Reduced risk improves the part quality over the life of the mold. More efficient part ejection contributes toward more optimized cycle times which lower piece price and increase speed.