Microfluidics in Injection Molding

Table of Contents

ToggleAchieving Ultra-Small Features and Tight Tolerances in Microfluidic Applications

Situations with Microfluidic Systems

- Super Small Features in the Microns

- Extremely Tight Tolerances

- Low Tolerance Variation

Your application needs microfluidic systems, and you need super small features in the microns with tight tolerances. The feature sizes need to be within an acceptable tolerance range and machining tolerance band range, which is the range of acceptable dimensions for your product.

If your plastic application relies on micro channels to move fluid, you need super small features that get down into the microns. When your tolerances only allow for variation of a few microns, the slightest shift can render your application defective. Whether your application is diagnostics, filtration, or separation, you cannot risk channel deformation or blockages.

Microfluidics Applications: Design in Practice

Watch the video to hear an explanation from engineer Mike Botta. He goes into detail on a particular case study in using this solution in a real-life microfluidics project. Connect with Mike Botta about your application.

Achieving Necessary Dimensions in Microfluidic Applications

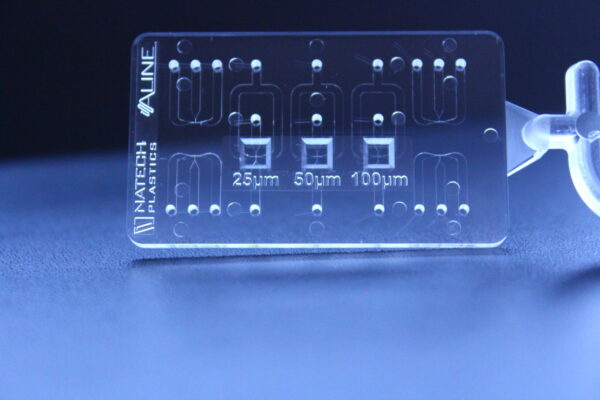

For microfluidic applications, the products depend on having significantly small features to control the fluid. Many of the conventional injection molding techniques and mold making practices are unable to create geometries that are small. Some geometrics are as small as 25 microns, which can be as small as a quarter of the size of the diameter of a human hair. When considering something that small, we have to innovate and investigate different manufacturing techniques.

Extremely small features in microfluidic systems are great for clients because they allow small volumes of fluid to be easily manipulated, which provides more precision than conventional systems. The small channel sizes have low volume requirements of costly samples, short analysis times, and a high level of control over how the fluids mix and interact.

Improving Inspection

After running trials and molding pieces, we have consider how to inspect these extremely small features. Conventional measuring tools and calipers are not appropriate for measuring these channel sizes.

Extremely tight tolerances are critical to microfluidic applications. Any variation in the channel width or flatness created by molding tolerances will influence how the fluid flows in the channels. Holding a tolerance of +/-3 microns maintains the cross-sectional profile of the channel.

What starts off as a journey to create seemingly impossible microfluidic channel geometries, results in the successful incorporation of various technologies, some established and some novel, to create these small challenging features in a scalable way.

Download Design Readiness for Fluidic Application Checklist

Before you begin tooling for your fluidic application, refer to this checklist. By reviewing a few key considerations, you will save yourself time, money and resources.

Let our team support you in applying this innovative approach on the development of your microfluidic device.