Microfluidics: Breaking the Rules to Achieve Scale

Testing limits of conventional molding for microfluidics helps lower time and costs spent during product development.

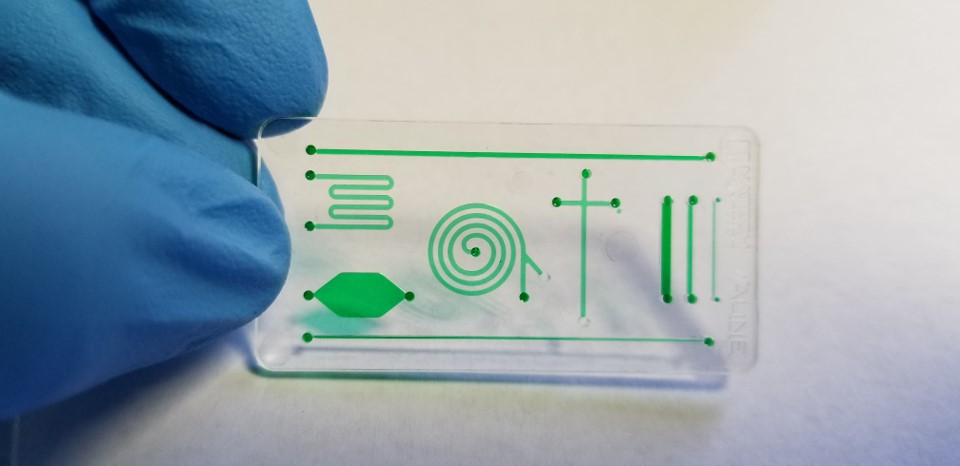

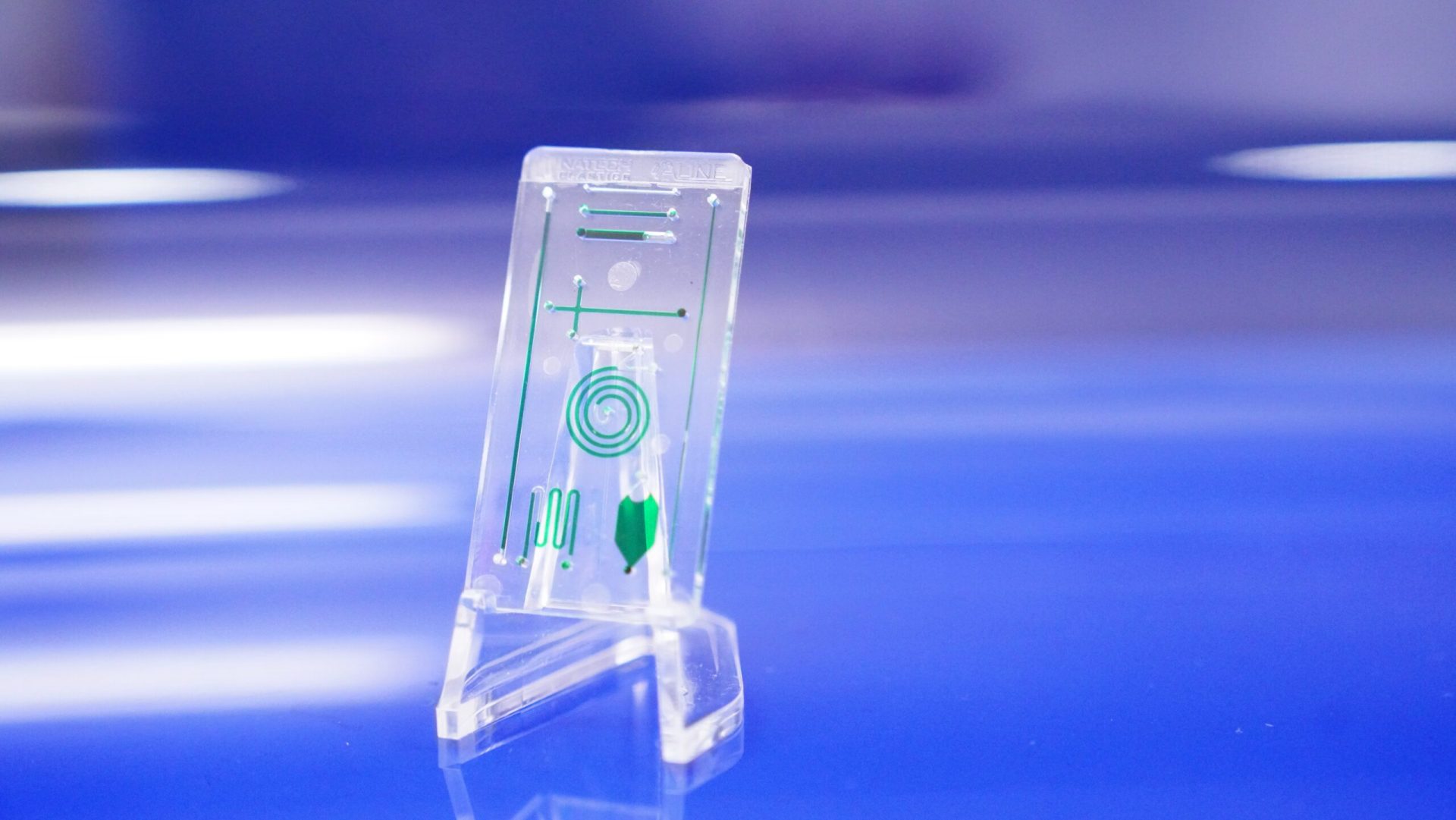

The Natech team has developed a process to build a mold for microfluidics chips at a cost of $10,000. The lead time from production-ready CAD to samples is as low as four weeks. Pushing the boundaries of what is possible using conventional moldmaking and molding resources has allowed the team to remove time and cost drivers from the process.

As technology advances, we’re moving toward smaller applications. The goal is to fit more into less space. Fluidics is following the same path and the industry is pushing the boundaries of what is possible. What has been done in a full lab can now happen on a single chip. This removes many steps in the process, reduces the chances for human error, saves time and money per test, and decentralizes the testing to get closer to the point of care.

Microfluidics Standards and Requirements

Fluidic channels have shrunk down to 500 microns and can be as small as 20 microns. In microfluidics applications, the reagent introduction, fluid mixing, and fluid control rely on extremely small features to control the fluid.

Not only are the tolerances tight, but there are high flatness precision requirements because the channels depend on a proper seal. Without a flat, even surface, the seal of the channel loses integrity, and the system fails.

Scaling Microfluidics, Reducing Lead Times and Costs

From a manufacturing perspective, we want to push conventional rather than specialized methods to achieve scale of smaller features and tighter tolerances. Conventional methods would reduce lead times and costs.

The process from initial R&D breakthrough through full-scale manufacturing can be summed as:

1. Achieve it once

2. Replicate it

3. Scale it up

This means we need to do more than just make a handful of parts work. We need to find a long-term manufacturing solution to scale production. While manufacturing using a specialized mold fabrication process helps to achieve scale, it can come at the expense of cost and lead time.

Breaking the Rules

According to the published rules, this shouldn’t really be possible using conventional mold manufacturing, molding methods, and molding materials. Each material brings its own set of rules. For example, metals typically achieve tighter tolerances than plastics. Different plastics families, different plastics grades, and even different plastics manufacturers can have different rules.

Instead of following the rules without question, we can break and redefine the rules.

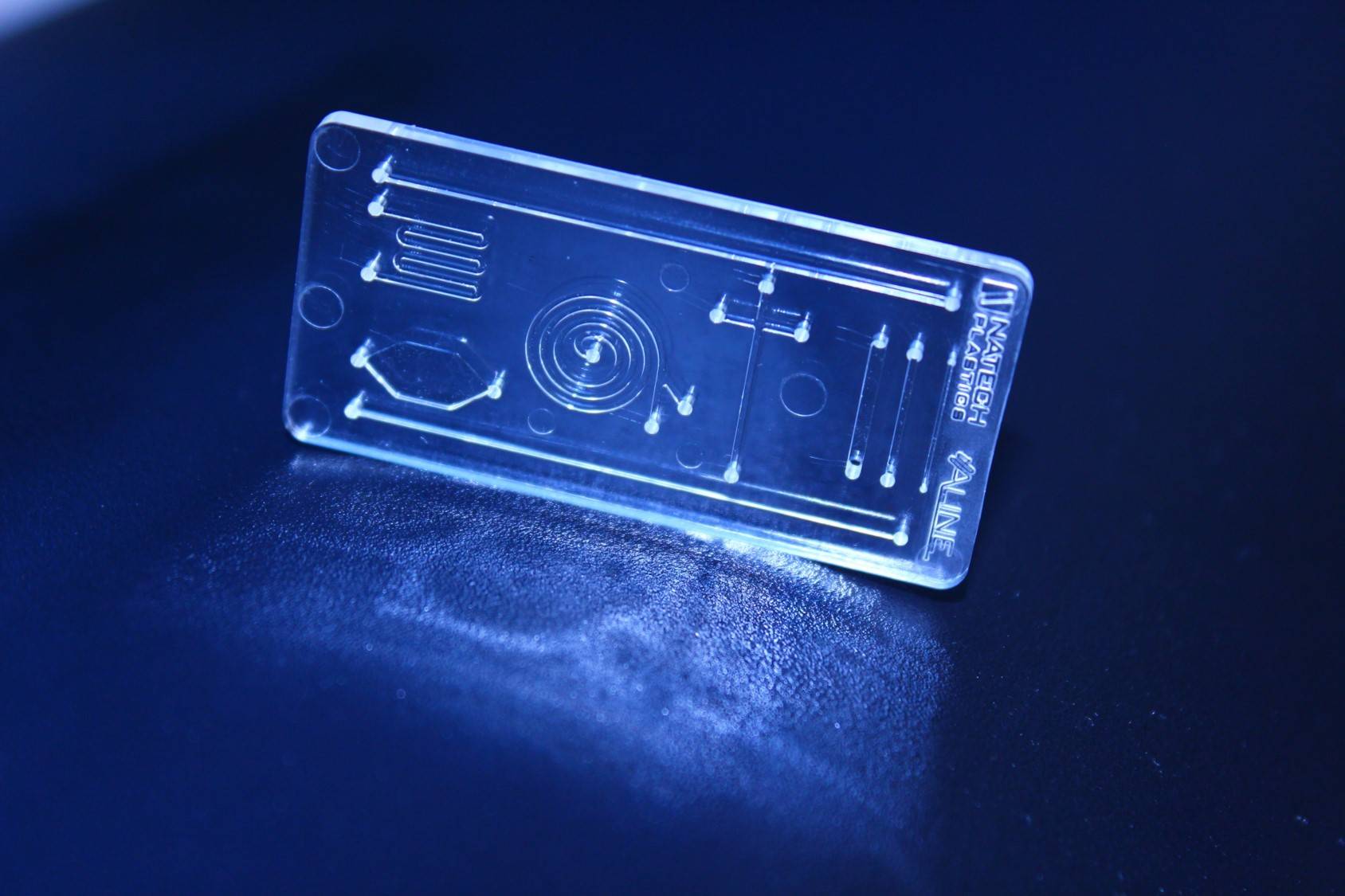

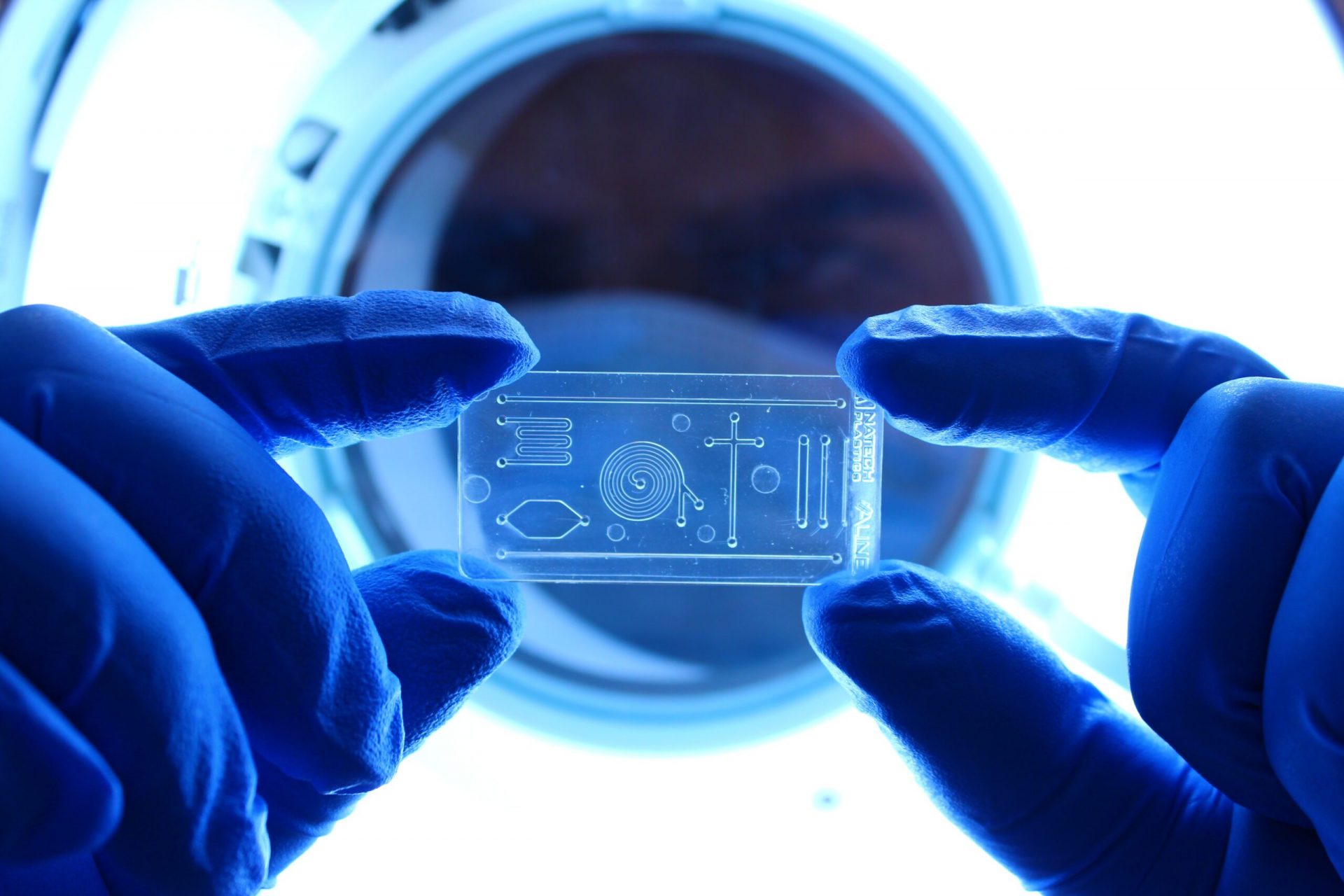

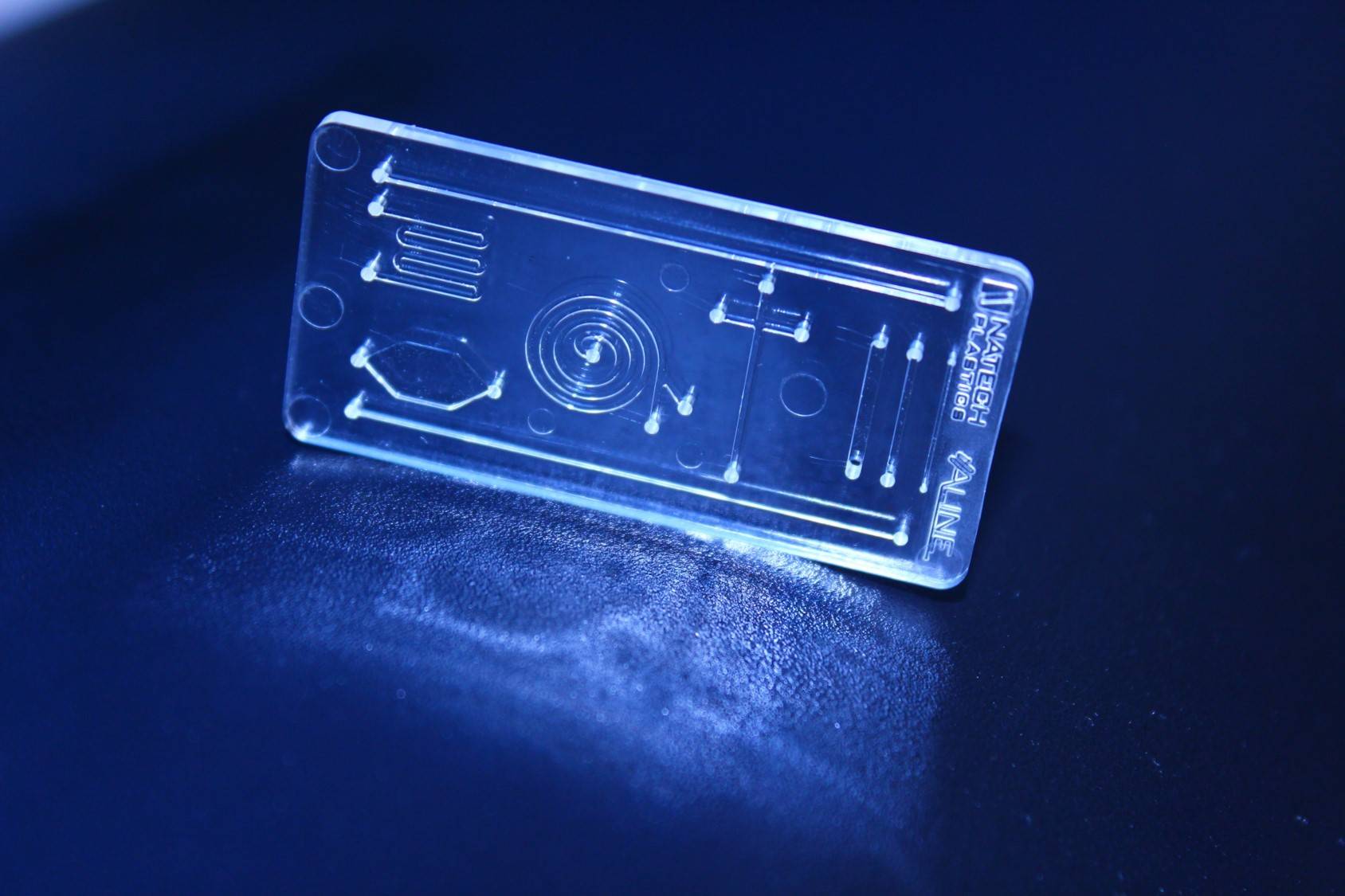

The team had previously achieved 300-micron channels with successful performance and wanted to go smaller. The A-Line collaboration included 250-micron channel width and a 2:1 aspect ratio of channel at twice the depth relative to width on a COC chip.

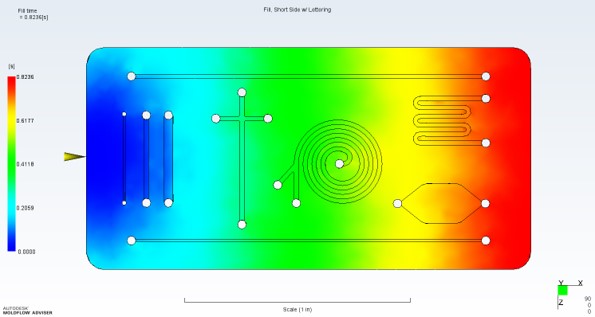

Our process engineer ran multiple iterations of Moldflow analysis to determine the optimal gating location. The mold was built and sampled in four weeks. The very first samples were filled, sealed, and the channels were successfully loaded with liquid without observable leaks.

Hitting the micro tolerances on the micro features using specialized methods had previously been accomplished. Doing the same at scale using conventional manufacturing methods would reduce costs and lead times but also improve the control of quality.

Our Microfluidics Capabilities and Accomplishments

Natech has the ability to manufacture microfluidic chips at a cost of $10,000 in as low as four weeks.

While many micro channels cannot be sealed, we were able to achieve channel seals. Natech manufactured the parts in a scalable way using conventional manufacturing methods to achieve smaller features and tighter tolerances than the material manufacturer said was possible.

To speak to a Natech engineer about your program, schedule a time to meet with an engineer.