Natech Adds 6 New Pieces of Equipment to Cleanroom Manufacturing Space

Natech Plastics

Ronkonkoma, NY, November 10, 2021

NATECH EXPANDS CAPACITY AND CAPABILITIES WITH 6 NEW PIECES OF EQUIPMENT

Natech Plastics expands its capacity and capabilities by introducing 6 new pieces of equipment in the fourth quarter of 2021.

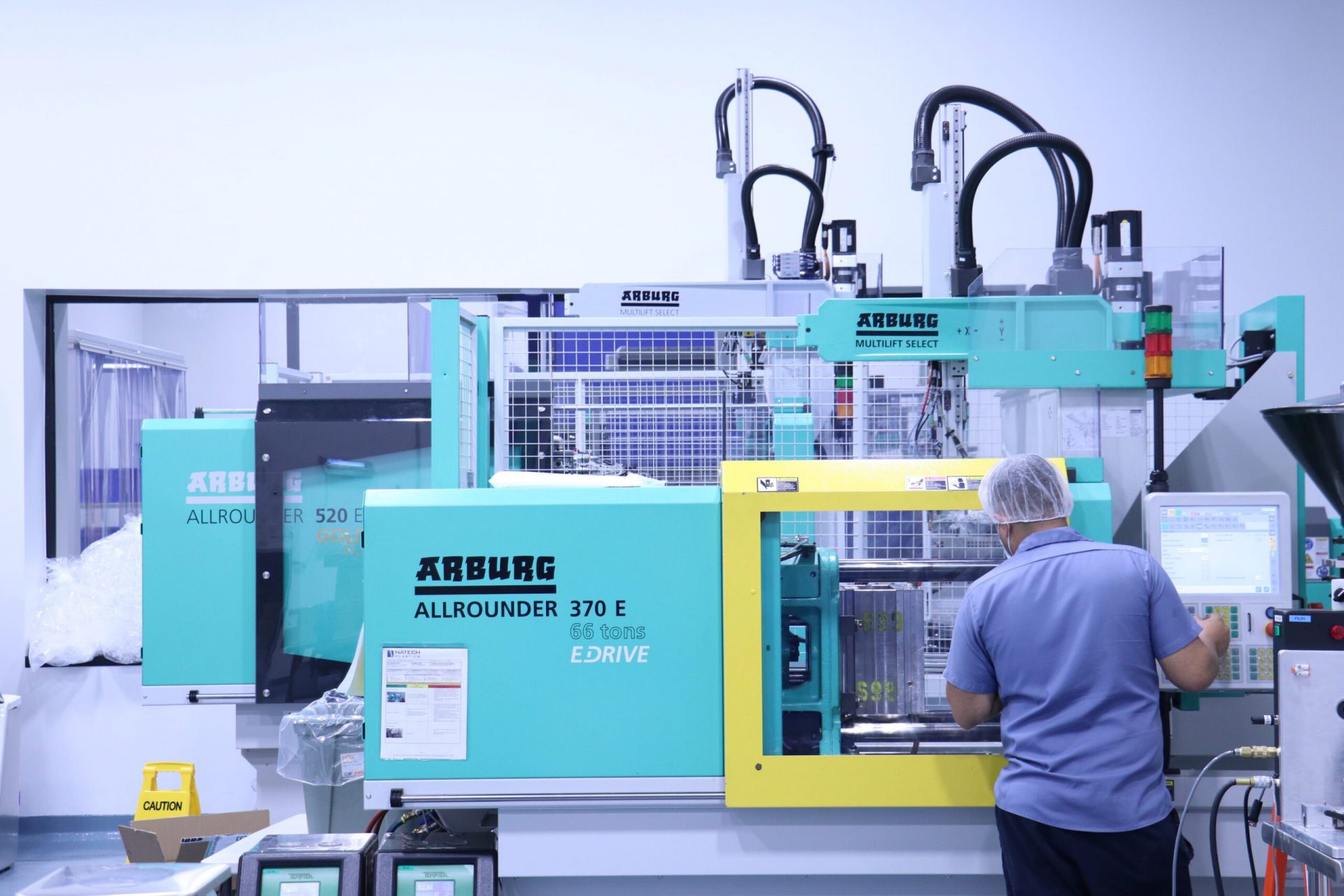

Two Injection Molding Machines

Natech adds two ARBURG injection molding machines to their headquartered location in Ronkonkoma, now having a total of 16 presses. This facility houses an ISO Class 8 Cleanroom, engineering and design services, and secondary operations. The two machines, alongside the cleanroom, will be used to manufacture medical and diagnostics products to support medical device and biotech startups in need of injection molded plastic components and finished devices.

Compared to less advanced injection molding machines, the new ARBURG machines allow for deeper insight and increase control over process variables. Because the machine, conveyor and robot are all integrated, it streamlines the manufacturing process.

Natech’s cleanroom maintains cleanliness throughout the manufacturing process, from the molded part to the final assembled product.

“In a post-COVID world, demand is high for quality medical devices. We want to serve our customers as expeditiously as possible,” Mike Botta, Engineering Manager said.

Across the plastics industry, the average age of an injection molding machine is 15 years, but Natech aims to keep their machines new and below the industry average, so they can produce parts as reliably and quickly as possible. The new machines have a high degree of precision and reduce lead time, which is crucial for the fast-paced medical device and diagnostics industry.

Four Filling and Sealing Machines

Natech adds four new filling and sealing machines to its cleanroom space. The machines were custom-designed and built for Natech. They have a modular, interchangeable design that allows for a variety of processes (filling, capping, heat sealing) to run on a single machine. A built-in shuttle allows filled product to be easily transferred to the sealing station.

Natech’s engineers must conduct process validation for each product that requires filling and sealing. The purpose is to quantify the repeatability and long-term stability of the process being run. This involves testing different process variables like pressure and dwell time and developing process windows for the individual processes being run.

One application for these machines is the filling and and sealing of containers that house extraction buffers, which are then used downstream for rapid COVID-19 antigen tests.

Learn more about Natech Plastics and our commitment to helping medical and diagnostic companies at www.natechplastics.com.

About Natech Plastics

Natech Plastics is a contract development and manufacturing firm, located in Ronkonkoma, NY. Natech specializes in offering end-to-end services for clients in the medical device and diagnostics markets. Natech offers services in design, engineering, injection molding, assembly, filling and sealing, and packaging. Natech is certified ISO 9001, ISO 13485 and an FDA-registered facility, and operates an ISO class 8 cleanroom.