How One Pharma Team Beat Syringe Labeling & Assembly Issues

Solving Syringe Failures

When Growing Demand Meets Unreliable Performance

A pharmaceutical seller of a prefilled veterinary drug needed nearly ten million syringes each year from their supplier to meet demand. Each set was supposed to arrive preassembled with a syringe barrel, dispensing tip, and protective cap. These subassemblies were loaded into the client’s automated production line where they were filled with the drug and sealed from the back side with the final component: a plunger.

But inconsistencies with the pre-assembled components arriving from their supplier triggered major issues. The parts arrived with misplaced syringe labels and carton counts were off. Even worse, orders were delivered late, or incomplete, leaving their team scrambling to deal with the quality issues and delayed deliveries. This burned valuable time and eroded customer trust, ultimately costing them orders.

That’s when they turned to Natech to uncover the root causes and build a system they could rely on. As an ISO 15378-certified manufacturer, Natech employs good manufacturing practices (GMP) to reduce risks during the contract manufacturing of primary packaging materials for medicinal products.

Misaligned Labels Disrupted Automation

The Problem: The syringes were labelled through an in-mold labeling process, but they arrived with labels out of place. This posed the risk of end users being unable to read vital product information. It also forced the production team to slow down and manually intervene, wasting time, money, and introducing new opportunities for error.

The Investigation: The Natech engineers discovered that the plastic flow during injection molding was shifting the in-mold label. The plastic, flowing from one surface to another, acted like an avalanche, caught the thin edge of the label and dragged it, which varied its position. This affected legibility and caused downstream issues.

The Solution: Natech partnered with industry-leading experts to develop a modification to the best-practices leveraged by in-mold labeling (IML) systems. An IML ‘footing’ custom-tailored to the small scale and geometry of this part added a small ledge inside the mold to hold the label in place during injection. This protected the edge of the label, and anchored it against the outer wall without affecting assembly, filling, shipping, or end use. It was a subtle change with a big impact.

To ensure correct execution time and time again, Natech implemented an in-line vision system camera in the in-mold labeling process. This system automatically inspected each label’s position and rejected any nonconforming syringes.

The Result: Issues happened much less frequently, but any variation was detected at the point of occurrence. Labels consistently stayed in place, improving quality and speeding up production without the need for manual intervention.

Syringe Tips Detached During Filling

The Problem: Syringe tips were assembled before delivery and shipped to the customer where they were dropped into hoppers at the start of the fill-and-seal line to receive the liquid drug. During the loading of the feeder bowls, the tips were detaching from the barrels, causing in-line rejections.

The Investigation: The proposed tip geometry utilized an intermittent undercut feature to achieve the interference with the mating barrel component. The team conducted a pull force test in both axial and perpendicular directions to quantify the behavior.

The Solution: The team extended the undercut feature around the full 360 degrees of the inner diameter. This meant adding a few thousandths of an inch of plastic in a steel-safe fashion. This could be achieved with a fast, cheap, and efficient mold modification.

The Result: Natech achieved a 45% increase in the pull-off force. The stronger, centered fits held up to automation, with no more tip separations in the assembly process. This meant disassemblies wouldn’t interrupt the filling line. Very small changes in geometry can result in significant changes in behavior—in this case, the force required to decouple.

Caps Popped Off in Feeder Bowls

The Problem: The team thought they had solved the issue, but as development projects go, when one problem was solved, a new issue emerged. Once the tip was secured, the caps then started to fall off during the client’s filling process. This was a similar issue to the red tips, but more challenging to address because they had to work within a small target window of attachment force. The caps had to be secure enough to stay attached prior to use, but they could not be so secure that they would pull off the tips when the user tried to remove the caps.

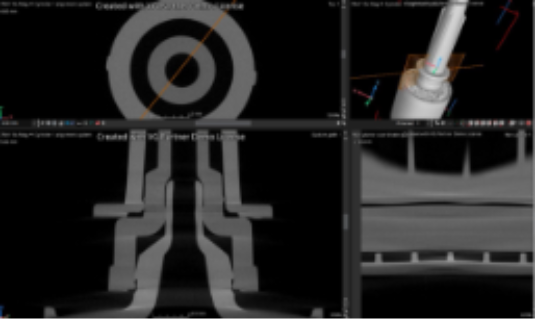

The Investigation: The snap fit between the two mating components was achieved with an interrupted undercut feature. To address this, Natech conducted a full inspection and evaluation of the existing components, leveraging OGP Smartscope and Mark-10 test systems. They even employed CT scanning to observe the assembly in cross-section. CT scans revealed that the tips’ undercuts demonstrated inconsistent concentricity, which weakened the fit. The CT scan revealed 50% variation from the nominal for this feature. This represented less than 0.002” inch variation.

CT scan showing an incomplete retention rib on the red tip—one of the reasons caps were detaching.

The Solution: The Natech engineers addressed the inconsistencies with the tips’ mold geometry, and updated the caps’ interrupted undercut feature to be uninterrupted around the inner diameter. Here, the team experimented with multiple geometries to assess their impact on the pull force and settled on a 0.002” increase to the feature depth.

The Results: Target pull force for cap removal was achieved. The team performed additional pull force tests and found the slight change in geometry resulted in a 43% increase in the pull force required to disengage the caps. This was high enough to prevent disassemblies during the filling process and was still low enough to remove without causing the tips to disengage. In other words, this achieved the desired balance to be strong enough to hold during loading but weak enough for removal during use. Caps remained in place through loading and handling, eliminating assembly rejects and preserving the flow of the manufacturing process.

An Integrated, High-Speed System

This wasn’t just three isolated fixes. Natech delivered an integrated syringe assembly system with:

• Precise in-mold labeling and label placement correction

• Reliable tip retention through part geometry tuning

• Cap stability achieved through geometry tuning and part matching

All of this operates at a cycle time of under 3 seconds per part, beating the original cycle time goal. And every piece is validated by real-world stress testing before it reaches the client’s automation line. Watch the award-winning system in action:

The Client’s Outcome

Now, the client no longer worries about random stoppages or unreliable parts. They receive fully assembled syringes, with labels in the right place, tips that stay put, and caps that hold on. Most importantly, they’ve shifted their focus back to what matters: serving customers and scaling with confidence.

Let’s Build Your Next Project Together

If you’re a pharmaceutical or diagnostics company struggling to get consistent results from your syringe assemblies or packaging suppliers, our team can help you.