September Employee Spotlight:

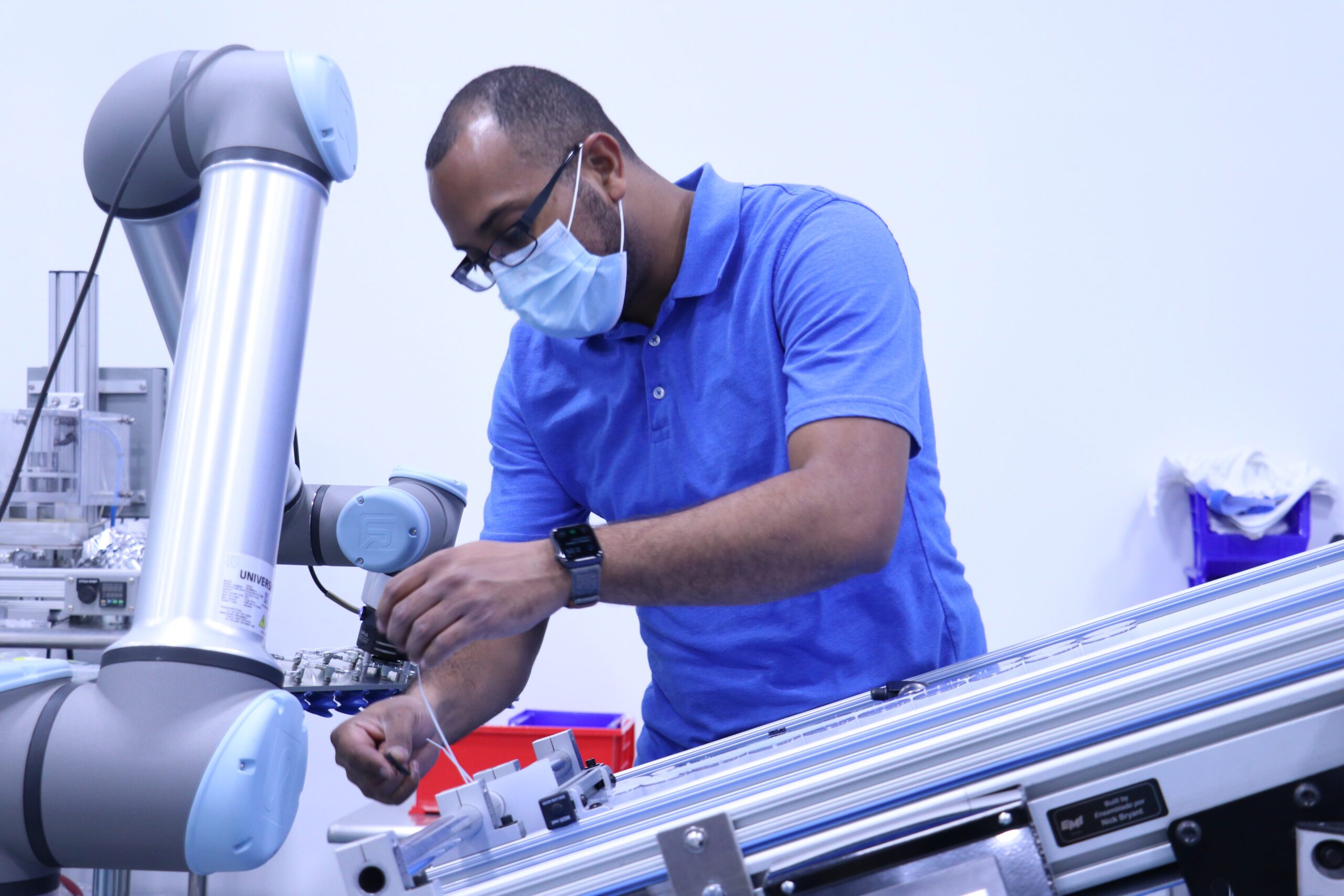

Joshua Romero

Principal Manufacturing Engineer

Joined Natech: June 5, 2017

Josh is an excellent leader and role model. He embodies the Natech person.

Mike Botta

Q: What do you do at Natech?

I’m the Principal Manufacturing Engineer, which involves understanding how to make a project into a full system. I take on all aspects of the manufacturing process, like mold design, end-of-arm tool, gating strategy, and automation, especially for higher volume jobs. I facilitate increased efficiencies and automation at Natech.

Working in different spheres is something that always gets me excited. I’ve always been a tinkerer. I’ve built machines in the past, like a CNC machine and I’ve built my own 3D printer. A lot of those system builds are fun because it’s like a jigsaw puzzle.

Q: What’s the most interesting thing you’ve worked on at Natech?

One of my favorites was creating a degating fixture for a medical part.

I watched the operator manually degate the part and saw they did a twisting motion, so I was like, what can I do from a machine design way to mimic what they do? So, I had an idea and I thought, this will work. It was a very unique way to degate the part because there was a twisting action behind it.

Q: What’s your favorite part about working at Natech?

I would definitely say the people, the people are great. Everything we do, we do it as a team. It’s really collaborative, which makes it easy to do our job. We always have unique, challenging things to do, which is a lot of fun.

Q: What is something that most people might not know about you?

I am an avid guitar player. I play a lot of music, mostly alternative rock. I used to be in a lot of bands back in the day and play on stage.

When I was younger, I liked planes and engines and making things go fast. And I used to be an airline mechanic. Technically, I’m six months shy of my full certification to be an airline mechanic to ground any flat I want. My background in college was actually internal combustion engines. So, I did a lot of engine research and combustion research, and I helped build the engines lab at Stony Brook with some other team members and my professors. Basically, I’m a gearhead.

Q: What do you like to do in your free time?

I like to hang out with friends, Ashley, and our dog, Porter. We like to take him out for little walks or hikes. I like to play guitar and sometimes I spend time working on making films with my production company.

Josh has amazing accountability and maintains connection with everyone, whether it’s within the company or with clients.

Jennifer Wrieske

Q: What’s one thing that you can’t live without?

I mean, the obvious answer would be food and water, but it’s definitely family and friends. They keep me grounded.

Q: Did you always want to be an engineer?

Since I was a kid, I already knew I would be an engineer. I liked taking things apart and seeing how they worked, how I could fix it, and what I could do better. I’ve even taken apart automotive engines just for fun.

Q: What about engineering and manufacturing is most fulfilling to you?

I like to take the idea out of my head and make it real. If it has electronics, wiring and software mechanicals, then it’s a homerun.

Q: What is your proudest achievement while working here?

Working on the shimmer cobot cell and being able to guide our new automation engineer, Sarah. And being able to see that it’s running on the floor with such a low integration time.

Q: What motivates you?

I really want to know how stuff works and I like being able to contribute to making stuff work. I also like teaching others. Mentoring and teaching others is a big thing to me. So, I like to help the others out, because I’m only going to be as efficient as everyone around me is.

It’s also a lot of fun to come up with unique ways to do something. In my head, I think “What if I do this? What if I do that?”

Q: What are three traits that define you?

Creative, because I like to think of different things and how to do them. Teacher, I like to teach. Respectful.

Q: What are three traits that define Natech?

The can-do attitude, the ability to get the work completed, and learning everything you can. Everyone here has a drive to really learn.