Quality Manufacturing

Optimizing your consumable for manufacturability, quality, and cost

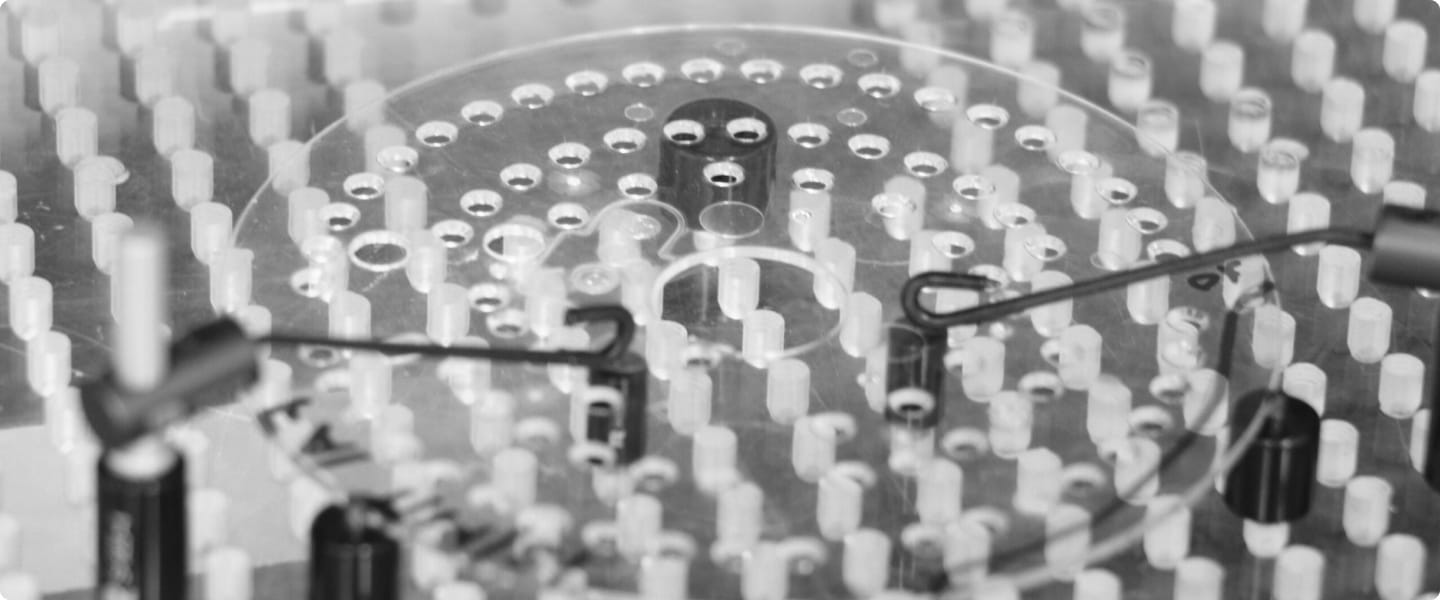

All-in-one flexible manufacturing solutions for complex, novel, life science consumables

Natech provides comprehensive solutions for the pharmaceutical industry, offering precision injection molding, automated assembly, and sterile packaging services all in one facility. Our in-house capabilities ensure strict adherence to quality standards and regulatory requirements, making us a trusted partner for delivering safe and reliable pharmaceutical products.

Contact us to learn how we can support your pharmaceutical manufacturing needs.

Natech provides comprehensive solutions for the pharmaceutical industry, offering precision injection molding, automated assembly, and sterile packaging services all in one facility. Our in-house capabilities ensure strict adherence to quality standards and regulatory requirements, making us a trusted partner for delivering safe and reliable pharmaceutical products.

Contact us to learn how we can support your pharmaceutical manufacturing needs.

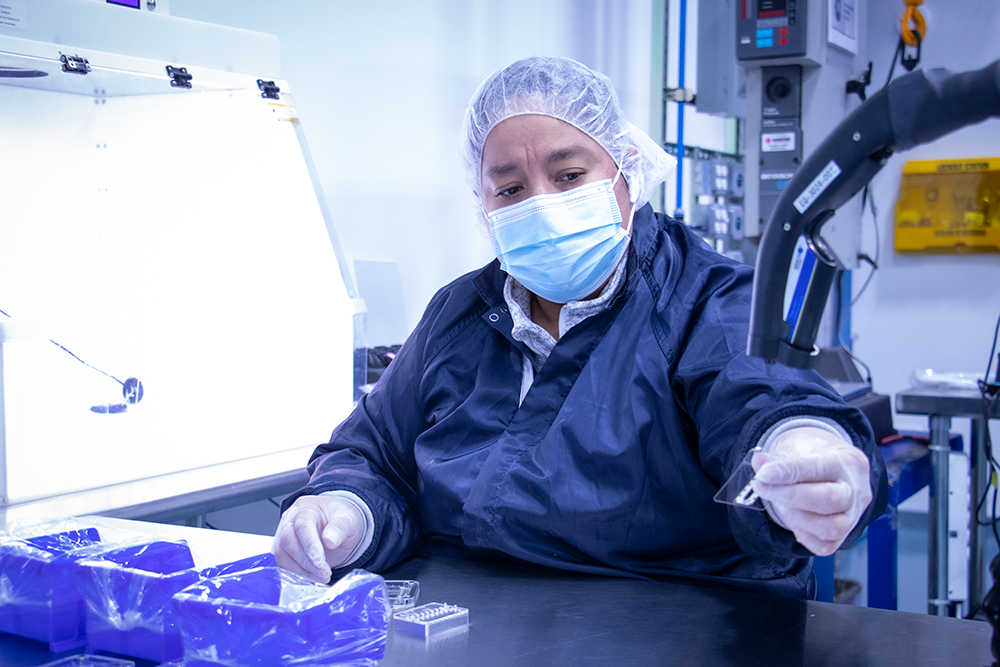

Natech helps medical device manufacturers overcome challenges by offering a vertically integrated solution that covers everything from design and injection molding to assembly and sterile packaging in its class 8 cleanroom. By keeping all services under one roof, Natech streamlines production, reduces costs, and ensures quality for clients, helping them move seamlessly from concept to final device.

Contact us to learn more about our medical device solutions.

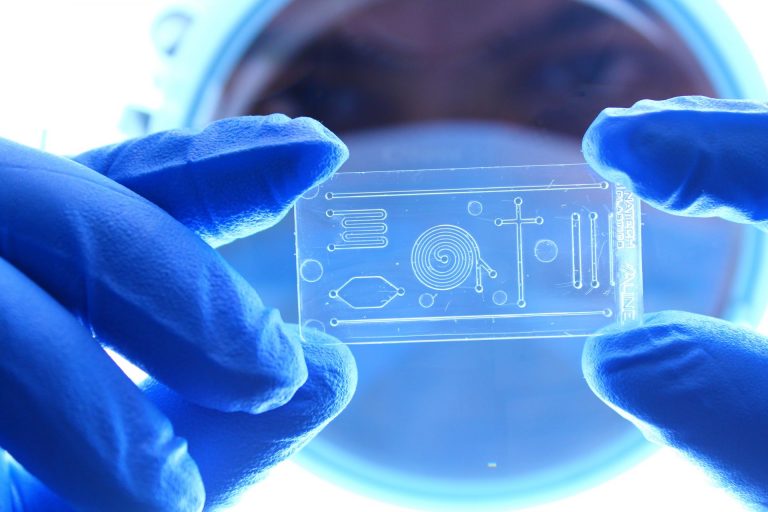

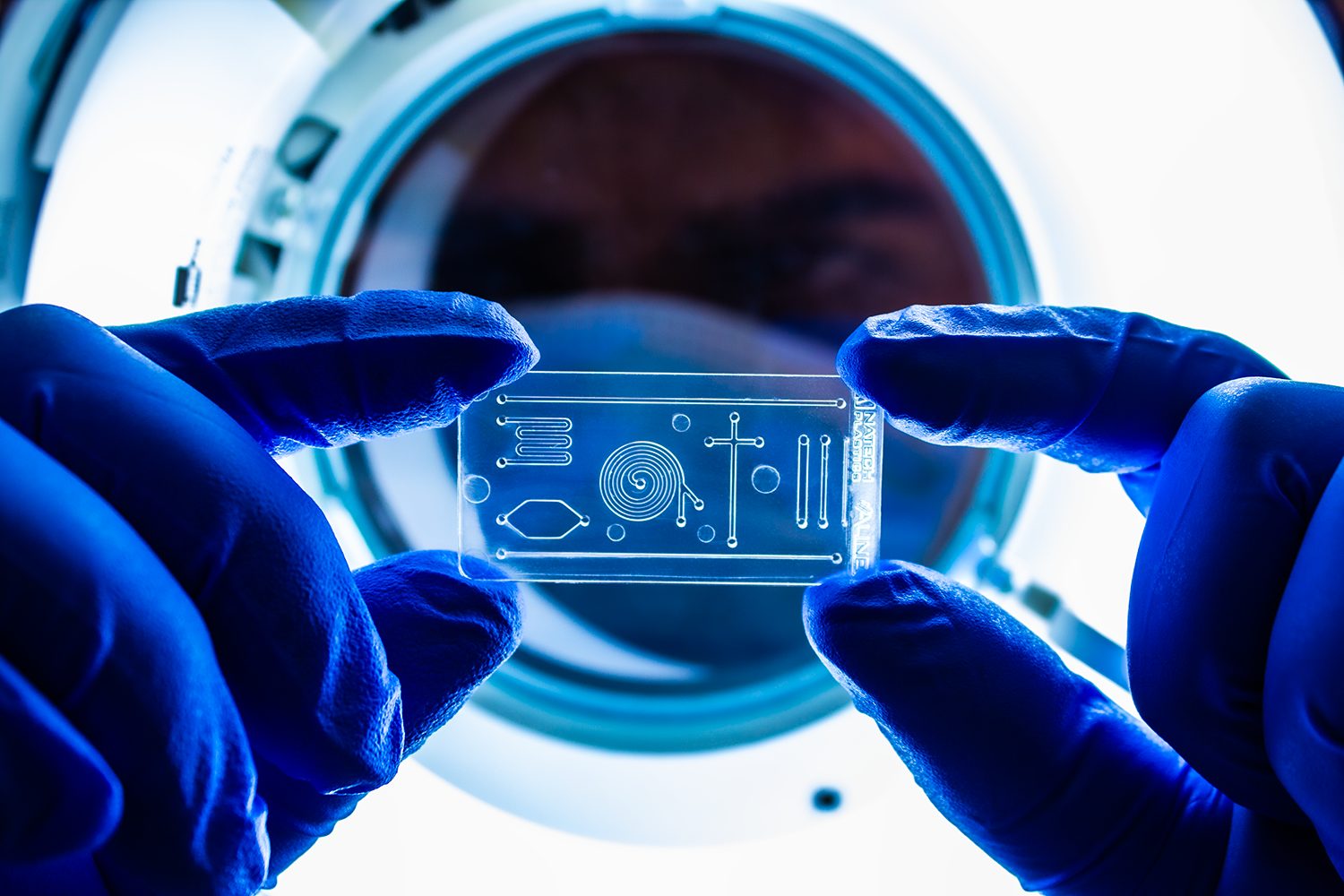

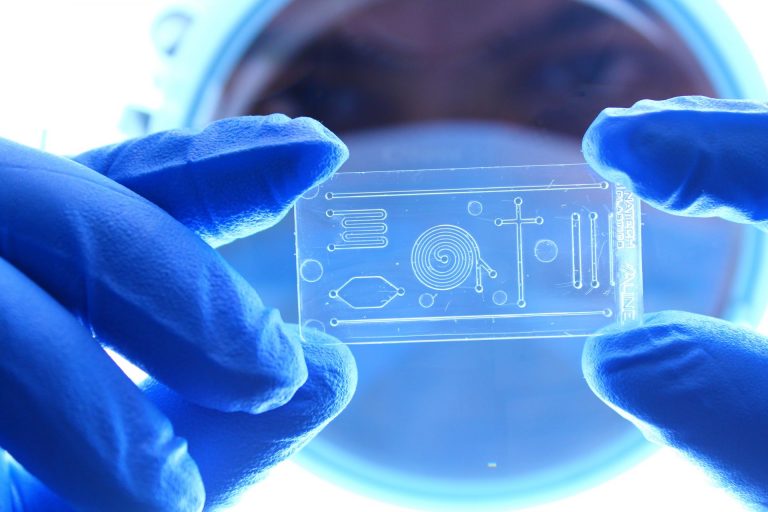

Natech uses Design for Assembly (DFA) principles to optimize IVD cartridges, ensuring secure seals and precise fluid control. By addressing assembly challenges and incorporating feedback mechanisms, we enhance product reliability while preventing leakage.

Contact us to learn more about our clinical and IVD cartridge solutions.

Optimizing your consumable for manufacturability, quality, and cost

Designing and building molds in-house for faster turnarounds and higher accuracy tooling

Scaling complex assemblies, including laminate stack ups,

welding, filling and sealing, and finished devices.

Send it to our team of experts and we’ll

quote it for you.

Here comes a short line about the the purpose of this section.

Contract manufacturing is the outsourcing of the production of parts or finished devices to a third-party manufacturer. Natech provides full contract development and manufacturing services, supporting clients from concept to high-volume production.

Natech offers a wide range of services, including product development, injection molding, part decorating, automation, product assembly, and filling and sealing. These services are designed to streamline the process and deliver high-quality finished devices efficiently.

Part decorating at Natech improves both the appearance and performance of molded parts. We offer capabilities such as hot stamping, labeling, pad printing, silk screening, and laser marking, which can enhance your product’s branding, functionality, and overall look.

Natech utilizes automation to improve part quality, enhance process control, and reduce costs. With machines equipped with 3-axis robots and custom automated solutions for inspection and assembly, we help scale your project seamlessly from semi-automated to fully automated production.

Natech serves industries such as medical devices, pharmaceuticals, diagnostics, and consumer products, providing end-to-end solutions that include design, molding, assembly, and packaging.

Natech’s engineering team customizes the assembly process to meet your product’s specific needs. We offer semi- and fully-automated assembly, ultrasonic welding, heat staking, pinning, gluing, custom packaging, kitting, and mechanical assembly to ensure an efficient, scalable process.

For in vitro diagnostics (IVD) products, Natech provides customized filling and sealing solutions for both low- and high-volume production. Our capabilities include automated filling processes, foil sealing, capping, and packaging solutions like custom trays and blister packaging.

Natech’s automated solutions and scalable processes ensure a smooth transition from prototype to high-volume production. Our in-house expertise, combined with a focus on efficiency and quality control, allows us to manage large-scale production while minimizing costs and risks.

We follow strict quality control procedures throughout all stages of production. From the initial design phase to the final assembly and packaging, our team performs detailed inspections, automated testing, and maintains complete traceability to meet industry regulations.

Natech offers a comprehensive, end-to-end service that simplifies the supply chain and optimizes production. By keeping all aspects of the project in-house—from design and molding to assembly and packaging—we reduce costs, increase efficiency, and ensure full control over the manufacturing process.

Load more questions