Don’t let unexpected costs, delays and quality issues slow down your project.

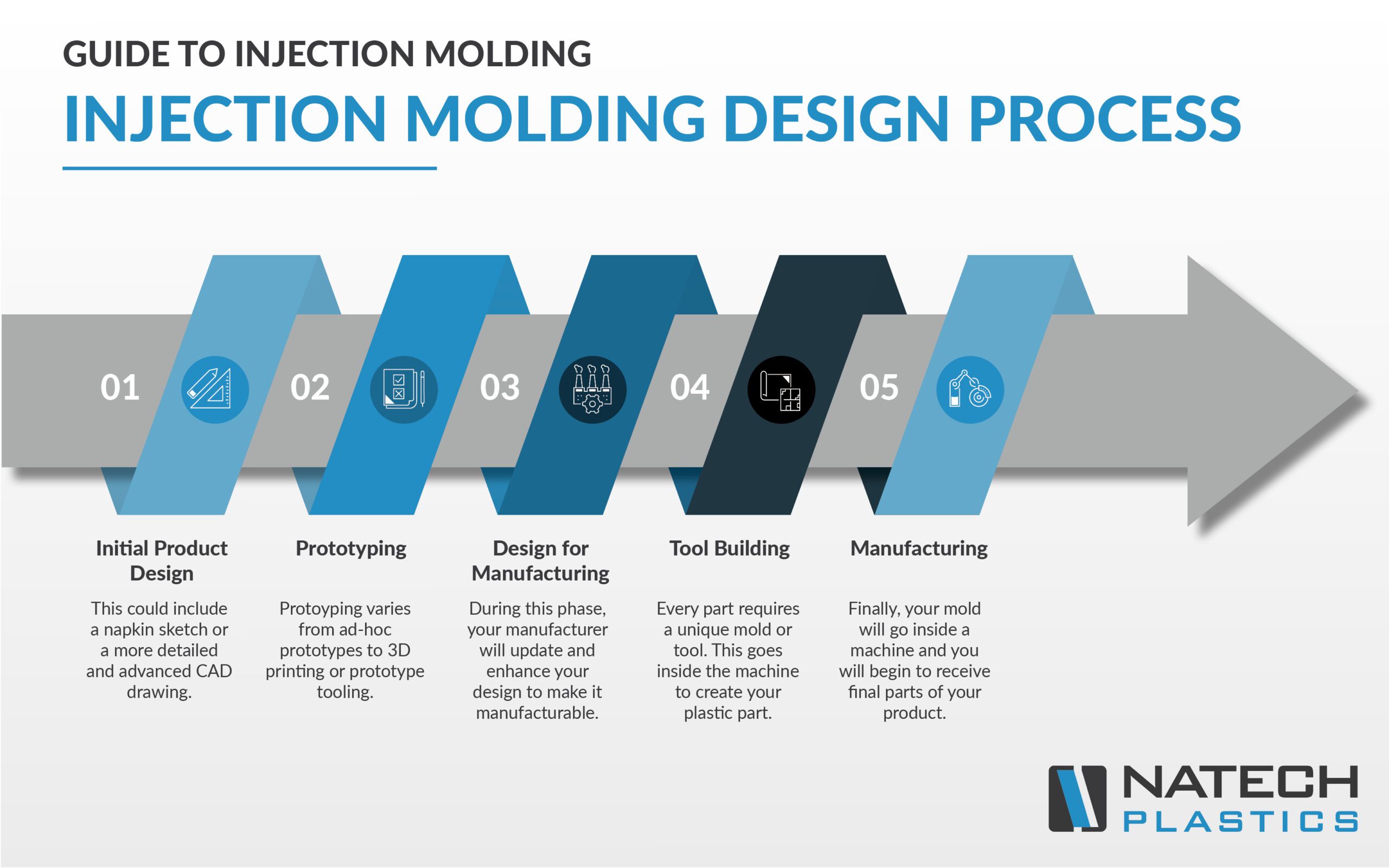

You have a game-changing or even a life-saving product idea. You’ve worked hard to take it from a napkin sketch to product launch, and now you’re ready to move from concept and prototyping to full-scale production. Being able to bring your product to market quickly is critical to ensure continued innovation, competitive advantage, mitigate long-term costs, and deliver products that positively impact your end-user.

According to Harvard Business Review, the biggest problem companies face when launching new products is lack of preparation – especially in the design phase. Even more to the point, roughly 70% of your manufacturing costs are decided during the design phase. This means missteps in design can more than triple your investment and delay your launch.

Don’t let that happen to you.

Design for manufacturing (DFM) allows you to avoid delays, unexpected costs and helps you prepare your design for full-scale production. In short, DFM looks at an initial product design and optimizes it for manufacturing.

Unexpected Delays and Costs & Unpredictable Timelines

“A lot of our clients get into prototyping thinking it is saving them time and money, but then are frustrated when it comes time for even small volume production,” shares Mike Botta, Natech’s engineering manager.

When it is time to manufacture your product, you need your design to be prepared for that specific manufacturing process. For instance, during design for manufacturing for injection molding (DFIM), your contract manufacturer will have their design and engineering team review and update the design. They will look for draft angles, vent locations, develop a gating strategy, and select the proper ejection systems. Much of this is not considered during the standard prototyping phase.

If your design isn’t ready for manufacturing when you want to move to production, you will need to invest additional time and money to update your design. This means your timeline increases anywhere from a few weeks to several months or more, along with the potential to more than double your costs. This can be avoided by investing in design for manufacturing early in the design stage, especially by using a DFM expert.

“I just spent all this money on design and prototyping, why do I have to pay more for design now when it’s time to manufacture?”

That’s the common question from clients when they see another price tag associated with design for manufacturability when it is time to move into production. Depending on your project and your design complexity, these changes can include anywhere from 2 hours to more than 40 hours of additional design and engineering work.

Each manufacturing process has unique requirements, specifications and considerations. Your design may work great in your initial 3D print, but when you move to injection molding, you now have to consider how plastic interacts in the molding machine and how you want your part to look and function. Many times, this involves design changes so that your part functions as intended, while maintaining the desired look and necessary quality standards.

Benefits of Using a Design for Manufacturing Expert

You have a great idea, and even with a great team in place, you are still likely to lose time and money without an expert on your side.

“There is a big difference between knowing how to design a product and knowing how to design something for manufacturing,” Botta shares. Having a strong partner with design experience related to your molding process saves your team in the short-term and the long-term.

Enhancing Your Product Development Experience

Even better, engaging with an expert early means having someone who can work WITH your team. Rather than feeling you are handing off your product idea to a stranger, a good manufacturing partner will work hand-in-hand with your team to help create a design that serves both your vision and purpose, and get you a product that is ready to be manufactured at low- and high-volumes.

Identifying Risks & Opportunities

When you are working with a partner that is an expert in that manufacturing process they can easily begin to identify:

Potential risks to product aesthetics

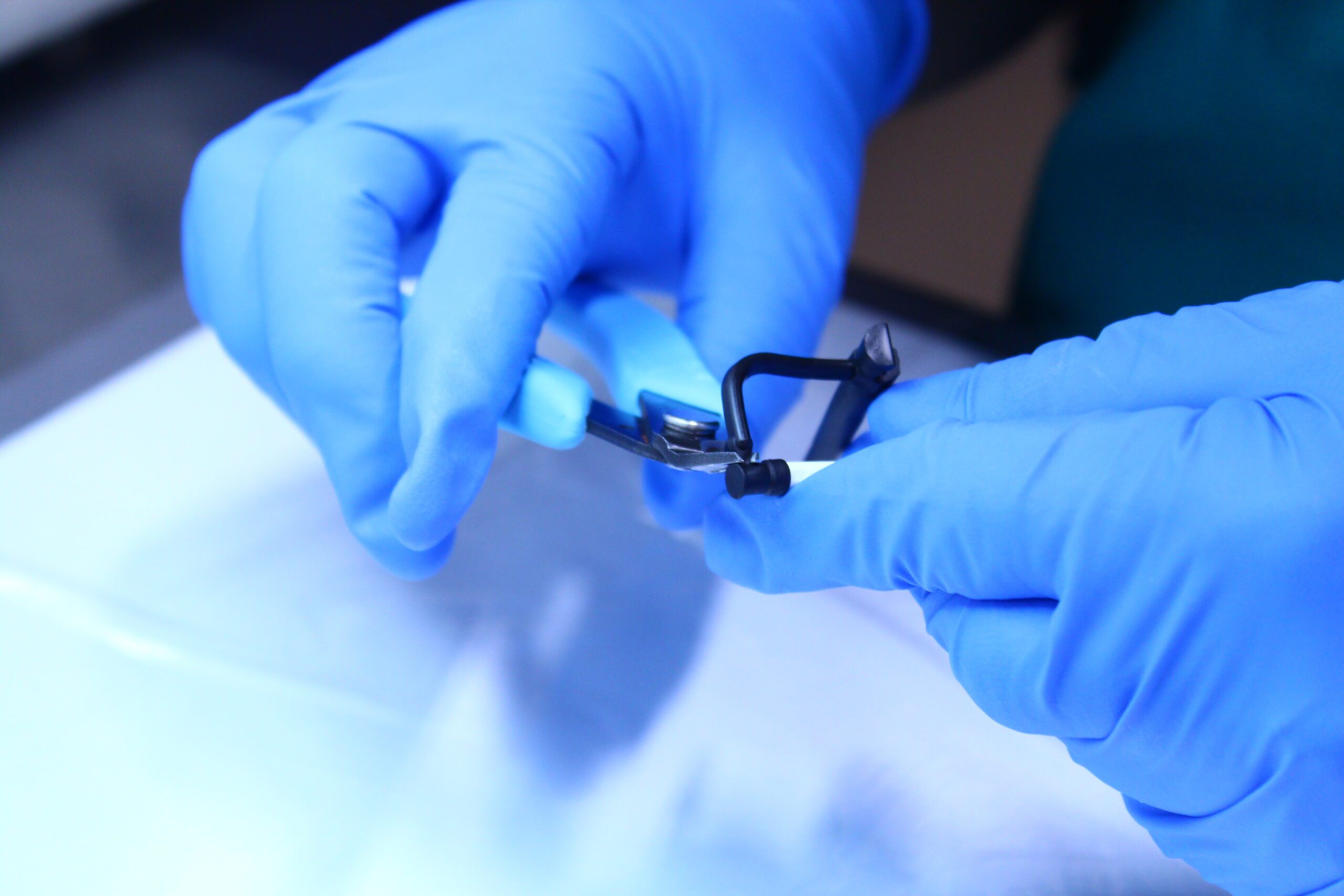

Depending on your goals, you may need to change your design plans to maintain the desired part look. This includes evaluating your part and the injection molding process to ensure there are no ejection marks or weld lines on specific areas of your parts.

Key Terms

Ejection Marks: Marks left where the ejection pins push the part out of the mold, causing an indentation These can be addressed by working with tool builders from the get-go to select an appropriate ejection system for you, or considering where the ejection will go in the design so that it’s not an aesthetic surface.

Weld lines/meld lines: Lines left where the plastic flow meets. These can be addressed by working with tool builders to gate appropriately (location on the part, type of gate).

Optimizing your design for injection molding up front can help you have the highest quality part. Common aesthetic issues like ejection marks, gate vestige, and burn marks can be circumvented by going to a DFIM expert first. You may not know what these aesthetic issues are, or even to anticipate them, and that is the benefit of going to an expert.

Potential risks to product functionality

It is likely that proper part functionality is your number one goal. Your DFM expert will be able to work with your design idea to enhance the product for its proper function and reduce risks of it breaking or malfunctioning once in use.

Opportunities to reduce complexity

On occasion, you may have created a design that is unnecessarily complex. Injection molding expertise comes in handy here, as it gives the engineer the ability to reduce either the number of part components, the complexity of the design or even revamp the design for lower-cost or easier processing.

Ways to prepare for future modifications

If this product is the first of its kind, you will likely have some small changes in the future. Working hand-in-hand with a DFM expert allows you to understand what can be done in the future to modify your part and your production mold – and what cannot be changed later. This saves you time, money, and stress down the line if you need to make design changes.

Plans to move from small to high-volume production

Once your product takes off, you will need to go from small-volume production to high-volume production. This transition doesn’t happen overnight, and you will want to be ready for both the cost and timeline associated with scaling up your project. By working with an injection molding design expert, they can coach you through this transition and help prepare you in advance.

The benefit of prototyping and moving to large-scale production with the same team is that that team a) understands the unique challenges with your part – what to pay attention to during design, tool build, processing, and quality inspection, and b) gains the learning from the prototyping to apply to the high-volume production – what works and what to pay attention to in processing, quality inspection, and assembly and actually being able to iterate the design if necessary for optimal scale up.

Each of these areas allows you to think beyond the current stage and into the future of your product. By identifying functional and design risks early, you reduce the costs spent building functional tooling, time spent testing, and increase speed from design to manufacture.

Risks of DIY Design for Manufacturing

Perhaps you have already assembled a team of top-notch designers and engineers, and you have invested considerably in product development. It is tempting for many start-ups and entrepreneurs to attempt to try design for manufacturing in-house, rather than pay to work with outside designers and engineers.

It can be expensive to hire a contract manufacturer, especially when you aren’t sure how your product will function. However, going at it alone can lead to considerably higher costs and risks for you and your project.

Delays and hiccups in your product design

Working with your contract manufacturer upfront for your design, means less back and forth communications later when you are ready to manufacture. Even small missteps in your design for manufacturing phase, can lead to long delays and even expensive tool changes if not caught in time.

Time and money lost during team learning curve

Nothing replaces experience, and when designing for manufacturing, having expertise in that process takes time. The learning curve to understand how to design for manufacturing properly and expertly is steep. This ends up costing you more paying for your team to gain experiment and gain knowledge rather than using those who already have the experience.

Lack of expertise to anticipate risks

Engineers and designers who are experts in designing for manufacturing can quickly look at a design and begin to anticipate potential risks. This includes risks not only in the design, manufacturing, and part quality, but also potential risks in assembly, distribution, supply chain and user functionality.

Future investment in preparation for manufacturing

Without the distinct experience, it is hard to properly prepare for future scaling and investment. You don’t want to invest too early in tooling that you may not need or that could potentially need to undergo major changes in the future. You also need to plan for investment in additional molds, machines, assembly, and partnerships. An experienced contract manufacturer can walk you through the process of planning for both near-term and long-term investments.

Your Partner in Design, Engineering, Injection Molding & Contract Manufacturing – With You from Start to Finish

Natech’s team brings an expansive and diverse set of skills to our clients. This means that regardless of your application, our team has an expert who can help you through the process.

As one of the founders of a diagnostics startup shared, “I talk with some of our vendors, and I end up leaving the call frustrated and with a headache. But I talk to Josh [a senior project engineer at Natech] and leave the call excited. It is great to have a partner who just gets it.”

Having the expertise, all in one place, means that you can move through each stage of project development and launch with confidence. Rather than having to source through a large supply chain of rotating vendors, you have your partner for design and manufacturing in one place.

Natech guides you through initial design and development, to mold building and material selection, into small production, and then scaling to high-volume product production. Even better, you have the entire team at your fingertips, but one point of contact to make sure your project is moving forward smoothly and you are getting the support and quality parts that you need.

Conclusion

If you are bringing your new product to market, unexpected risks, delays, and costs take away from your budget and your launch. Whether this is the first product you’ve developed, or you have launched products before (and experienced setbacks), reach out to Natech and see if partnering can save you time and money.