PRECISION MOLDMAKING

Our master moldmaking and high-complexity molds mean fewer repairs, optimized cycle times, and increased mold life.

Natech Plastics was founded by master moldmaker Gerd Nagler, and we continue his legacy of expertly crafted molds with our in-house master moldmakers. We build high-performance molds that last, so you can get quality parts.

All Natech molds are manufactured domestically, combining long-established knowledge with modern moldmaking techniques. Our moldmakers use CNC, EDM, milling and grinding to build molds that run automatically.

Our medical moldmakers build, qualify, and modify quality injection molds.

Capabilities

- Mold Design

- MoldFlow Analysis

- Steel Insert Configuration

- R&D Molds

- Production Molds

- Sampling

- First Article Inspection

Mold Durability

You might need a mold that lasts for over 1,000,000 cycles. Natech can help you choose a quality and robust mold early on.

Mold Design and Build

Mold designs are supported by mold flow analysis, cooling analysis, deflection analysis, and finite element analysis.

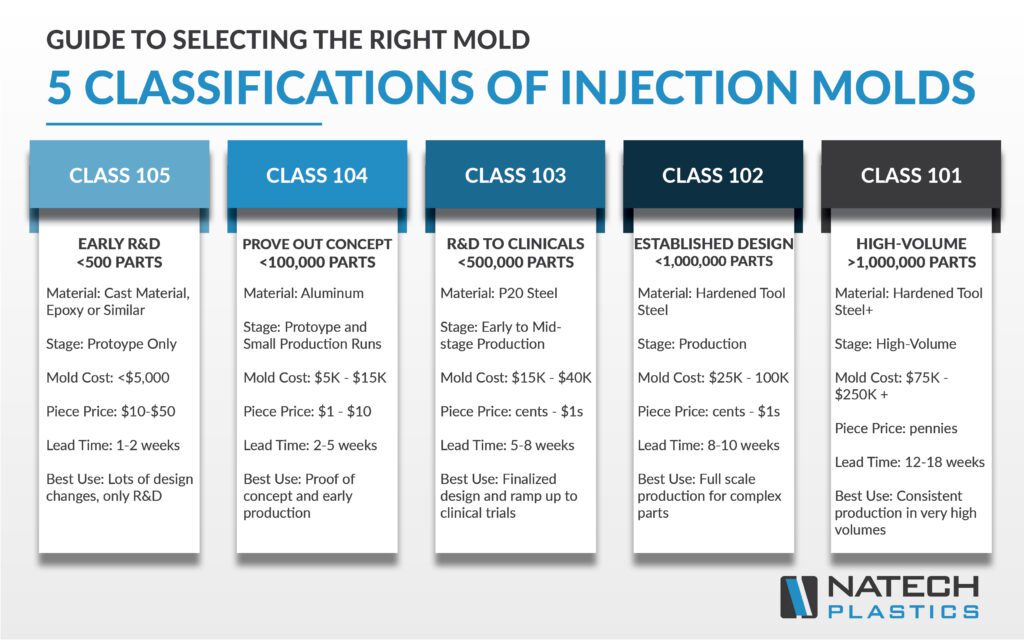

Natech uses SPI mold classifications, a mold classification system that is a standard in the moldmaking industry. This system helps customers compare different molds and understand the tradeoffs of each option.

For example, an Aluminum mold (Class 104) might be faster and cheaper to build, but it will not last as long. A hardened steel mold (class 101 or 102) might last for 1,000,000+ cycles, but the initial cost will be much higher.

Mold Maintainability and Repair

Every mold has a useful life. Extending the useful life of a mold brings savings and reduces risks.

Our moldmakers review molds requiring maintenance or repair activities. They utilize core and cavity blocks, core and cavity sub-inserts, shutoff inserts, polish inserts, and venting inserts.

Optimized Cycle Times

Our molds are designed for filling, cooling, and ejecting. Optimizing these factors improves cycle times, so you can start making your parts faster.