Beginner’s Guide to Design for Injection Molding: Inspection

Learn the Basics of Plastic Injection Molding: Designing for Inspection Success

Table of Contents

- Homepage

- Design for Injection Molding: Filling

- Design for Injection Molding: Cooling

- Design for Injection Molding: Ejection

- Design for Injection Molding: Assembly

- Design for Injection Molding: Inspection

The design for the injection molding inspection phase is a critical aspect of the overall injection molding process. While some changes may only appear on the part drawing, they play a crucial role in ensuring product quality. The 2D print, including a practical inspection plan and part tolerances, serves as a communication tool for manufacturers and inspectors to monitor and maintain product quality throughout production. Here are two essential actions that your manufacturer must take.

Make sure your manufacturer implements these two practices to ensure your part is designed for inspection.

1. Define Inspection Plans

Inspection plans establish clear communication between designers and manufacturers, minimizing the risk of accepting defective lots or rejecting good ones. It is essential to have well-defined requirements in place. Unfortunately, some drawings lack inspection plans, contain unmeasurable dimensions, or have excessive inspections, which increases risks and costs unnecessarily.

In cases where inspection plans are missing from the drawing, the engineer takes the responsibility to define the inspection plan during design for injection molding. This involves identifying critical dimensions, ensuring inspectors can accurately measure those dimensions, and specifying the appropriate AQL (Acceptable Quality Limit) inspection level.

2. Define Specifications

Specifications define the nominal dimensions and allowable tolerances for the part. Lack of tolerances leads to confusion and increased costs during manufacturing, while impractical dimensions introduce both cost and quality risks. Arbitrary and overly tight tolerances also escalate production costs.

During design for injection molding, the engineer determines critical tolerances and updates the drawing to reflect accurate part specifications. This ensures that manufacturing processes can be carried out efficiently and within acceptable quality standards.

Ensure Success During Manufacturing

Ensure exceptional product quality in injection molding by focusing on the inspection phase. Partnering with a manufacturer that prioritizes inspection success is crucial. They should define comprehensive inspection plans and specify accurate tolerances and dimensions in part specifications.

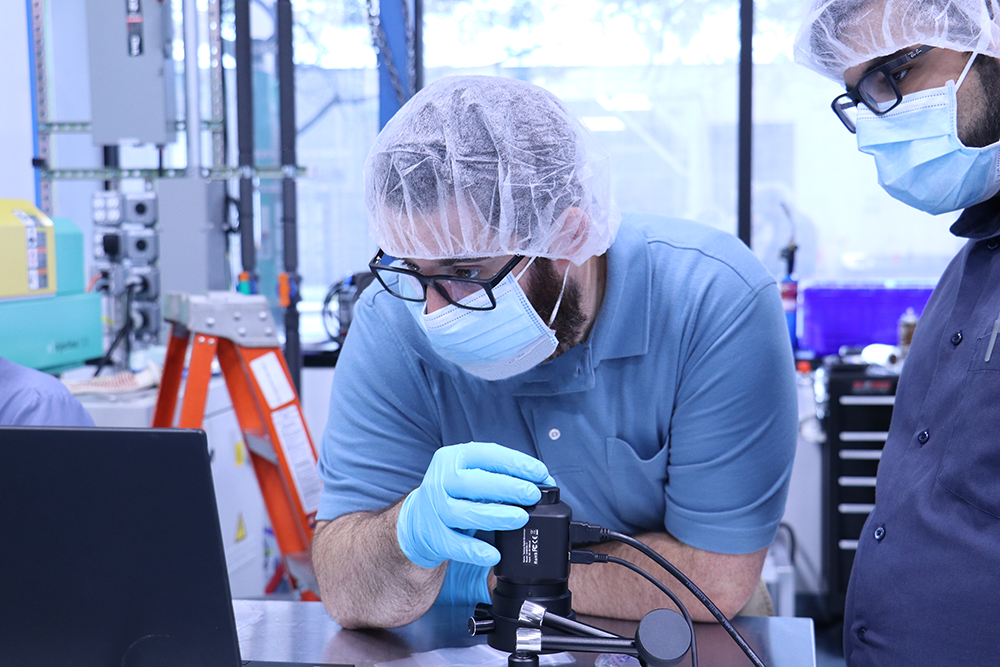

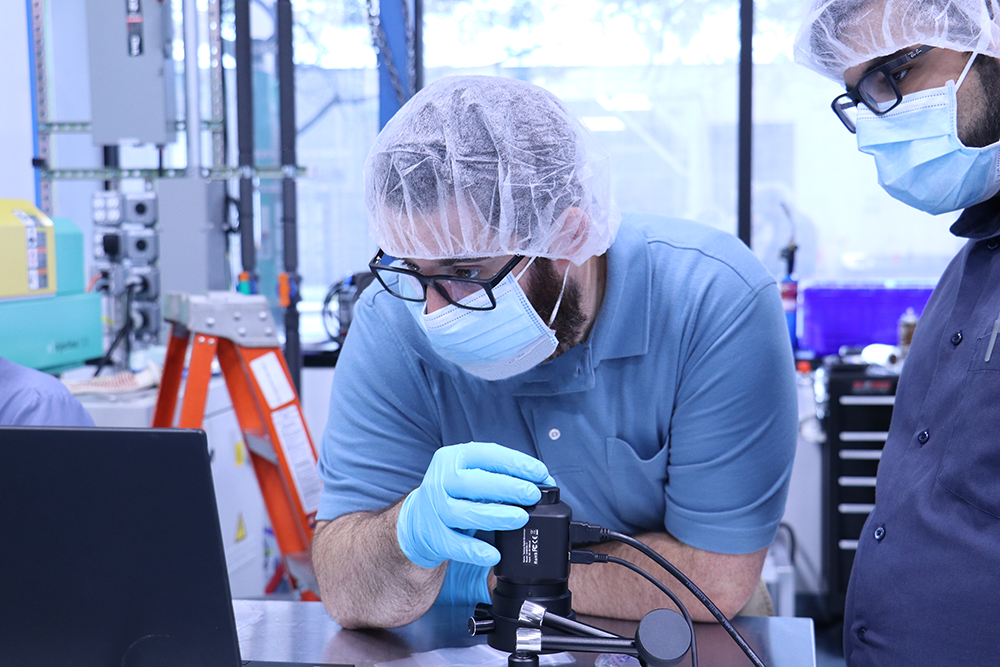

At Natech, we understand the significance of designing for inspection success. Our dedicated team implements robust inspection plans and precise part specifications to deliver the highest level of product quality. Partner with us for your injection molding needs. Contact us today to start your journey.

←Previous Post ㅤㅤㅤㅤㅤㅤ