Beginner’s Guide to Design for Injection Molding: Ejection

Learn the Basics of Plastic Injection Molding: Designing for Ejection Success

Table of Contents

- Homepage

- Design for Injection Molding: Filling

- Design for Injection Molding: Cooling

- Design for Injection Molding: Ejection

- Design for Injection Molding: Assembly

- Design for Injection Molding: Inspection

The design for the ejection phase in injection molding is a crucial step that ensures the successful removal of the part from the mold. Once the plastic has cooled and solidified, the mold opens, and the part needs to be ejected. However, due to the shrinkage that occurs during cooling, the plastic part tends to stick to the core side of the mold. Ejecting the part introduces the risk of deformation and the possibility of parts sticking to the mold and becoming trapped before the mold closes again.

1. Assigning Parting Lines

Situation

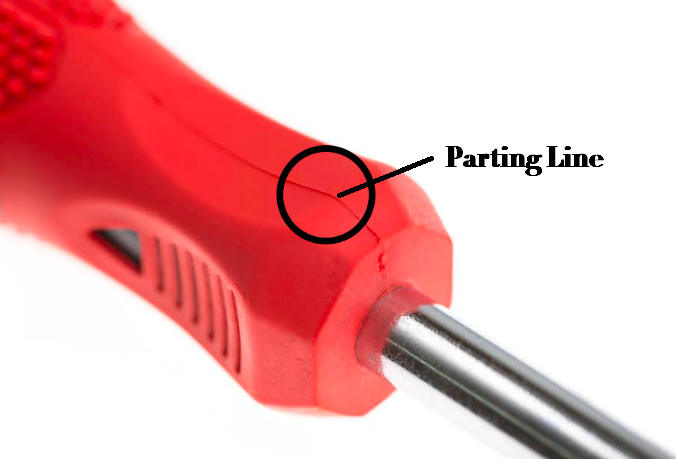

When the two sides of the mold come together, a slight gap is formed where they join, resulting in a parting line on the injection molded part. Parting lines can impact both the aesthetics and functionality of the part. Over time, as the mold naturally wears, the flash around the parting line can increase.

Solution

To address this, design for injection molding assigns parting lines to non-critical surfaces. Ideally, the engineer specifies an acceptable parting line dimension with a specific tolerance. This allows the manufacturing team to effectively manage mold maintenance and keep the parting line within acceptable limits.

Removing Undercuts

Situation

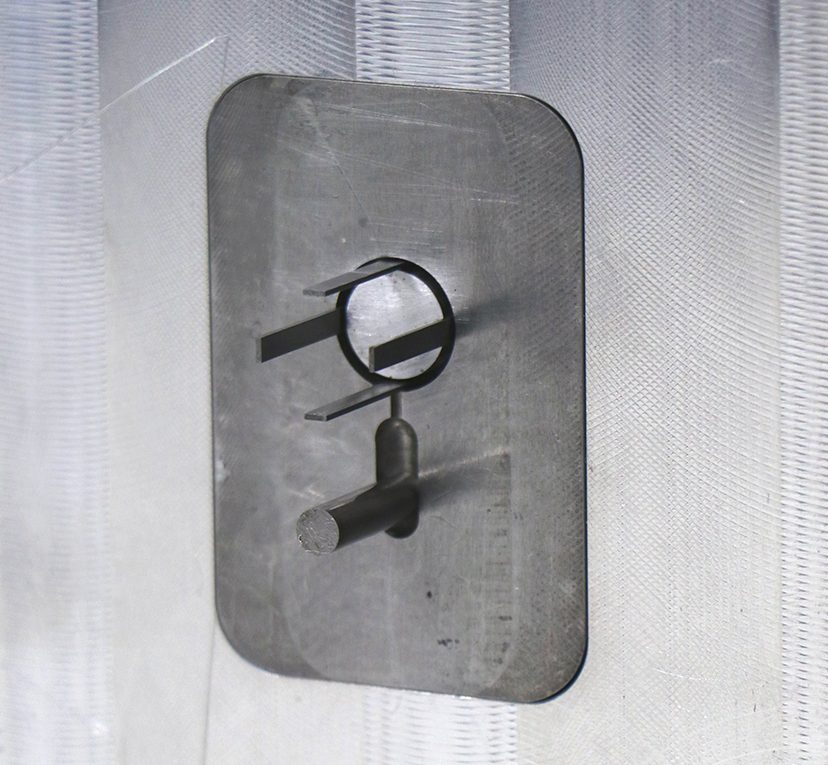

Undercuts are features in the mold that hold the part in place during ejection, but they can hinder the smooth removal of the part from the mold. While some intentional undercuts serve functional purposes, they can increase mold complexity and risk.

In the image below, you can see the snap feature that creates an undercut. Imagine the steel that would have to form that feature. Then imagine how the plastic engineer would move that steel out of the way to remove the part from the mold. Without forethought the part would be stuck inside the mold unable to be removed.

Solution

During part design for injection molding, the engineer explores opportunities to remove undercuts where possible. This can be achieved by incorporating a hole in the part to facilitate ejection from the other side. In cases where the part design cannot be altered, more complex mold designs such as unscrewing molds or collapsible cores may be necessary.

Defining Ejection Marks

Situation

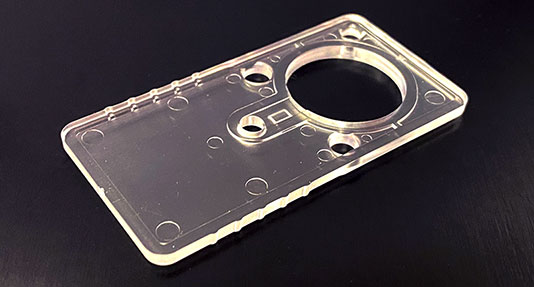

After the mold opens, the ejector pins extend outward from the core, pushing the parts off the mold. These ejection pins leave slight marks on the part. As the injection mold wears down over time, the flash around the ejector pin marks can increase.

Solution

The injection molding engineer must carefully consider the placement of ejection pins to ensure adequate ejection of the part from the mold. This requires balancing these locations with the aesthetic and functional requirements of the part.

4. Adding Draft Angles

Situation

The design of the part influences the force required to eject it from the mold. Without appropriate draft angles, parts with complex shapes, such as a syringe with a deep draw, can stick to the core during ejection. Excessive force during ejection can lead to part deformation.

Solution

To reduce the force necessary for ejection, the design for injection molding incorporates increased draft angles and may introduce a smoother polish on the core side of the mold. The CAD model should clearly depict the draft angles, and the 2D print should reference the allowable draft angles.

Ensure Success During Manufacturing

In conclusion, understanding the fundamentals of designing for ejection success in plastic injection molding is essential for ensuring a smooth manufacturing process. By addressing key considerations such as assigning parting lines, removing undercuts, defining ejection marks, and adding draft angles, manufacturers can overcome challenges associated with part sticking, deformation, and mold complexity.

Implementing these design strategies not only facilitates the successful ejection of parts from the mold but also enhances the overall aesthetics and functionality of the final product. By leveraging the principles of design for injection molding, manufacturers can optimize their manufacturing processes and deliver high-quality plastic parts that meet customer expectations.

←Previous Post ㅤㅤㅤㅤㅤㅤ Next Post→