Surface Finish Impacts Overall Part Manufacturability

Typically, a smooth surface on a plastic part should improve part ejection. However, that is not always the case. On occasion, a higher polish on the part actually hinders the part's ejection from the mold. Finding this out during production leads to major challenges and higher costs, which is why a solid problem-solving process during product development is critical.

Natech engineers utilize the scientific method for problem-solving when our clients encounter challenges. By forming an initial hypothesis, testing it, and interpreting the results, we can methodically solve many manufacturing problems. You can read more about the four stages of lean product development here.

Surface Finish Case Study Summary

Application

A curved core with an A3 finish within the injection mold formed the arced shape of the tube. The mold could not eject the part linearly, instead, hydraulic slides used linkages to translate linear motion into rotational movement. This revolved the curved core around a theoretical center point to pull the core from the part.

Problem

Over time the mold experienced normal wear and parts started sticking onto the core. This caused issues with the parts properly ejecting from the mold.

Solution

Vacuums between the plastic parts and the mold caused the sticking. The Natech team gave the core a glass bead finish to reduce the vacuum and allow air to flow around the textured ridges. Parts molded with this textured finish no longer stuck to the core. The parts now ejected smoothly.

APPLICATION

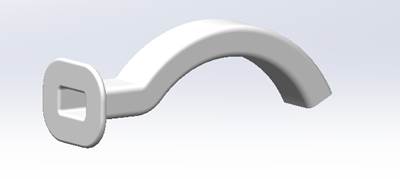

A medical client manufactured a polypropylene oropharyngeal tube at high quantities from a four-cavity mold. Medical professionals insert these tubes into the patients’ mouths to maintain an open airway. The curved shape of the device allows for ease of placement for medical professionals and safety for patients by following the natural curve of the mouth into the pharynx.

From a user standpoint, any form of part deformation could prove detrimental. Any deformations within the internal diameter can disrupt air flow to the patient. Deformations around the external diameter can cause oral trauma during insertion and even bleeding in the airway. It also makes insertion much more difficult for nurses and doctors.

A curved core with an A3 finish within the injection mold formed the arced shape of the tube. This increases the complexity of the mold because the mold cannot eject the part linearly. Before the part can eject, hydraulic slides use linkages to translate linear motion into rotational movement. This revolves the curved core around a theoretical center point to pull the core from the part.

PROBLEM: Injection Mold Wear Caused Parts to Stick

Over time the mold experienced normal wear. Parts started sticking onto the core, and the client turned to our Natech engineers for support. Our team followed the process of hypothesize, plan, test, and interpret to search for a solution.

HYPOTHESIS 1: Too Much Friction

They initially hypothesized that too much friction between the part and the core prevented movement. To reduce the friction, they tried a release coating on the core. This offered a way to test the hypothesis at a low-cost with little downtime.

The team ran the experiment and the part still would not move off the core. The release coating had not improved the ejection. This meant their initial hypothesis was wrong, so the team had to form a new hypothesis.

HYPOTHESIS 2: Vacuum Between Plastic Parts and Mold Causing Parts to Stick

Friction, undercuts, and vacuums between plastics parts and molds can cause sticking. The team eliminated friction and undercuts as causes. By process of elimination they then hypothesized that a vacuum prevented the part from moving off the curved core.

To test their hypothesis, the team gave the core a glass bead finish. This texture should reduce the vacuum that could form between the part and the core by allowing air to flow around the texture ridges.

The team molded parts with this textured finish. Parts no longer stuck to the core and ejected smoothly. Over time, the core had worn down to a smoother finish increasing the risk of forming a vacuum during ejection.

CONCLUSION

In certain cases, polypropylene tends to eject better from a slightly textured surface. This can seem counterintuitive as the texture might give the plastic part small undercuts to get caught on. However, the texture also serves to reduce the ejection risk introduced by vacuums.

By forming, testing, and analyzing a hypothesis, you can devise quick and easy tests of your assumptions. Oftentimes, true learning depends upon our ability to shatter our own assumptions.

Connect with the Natech Engineers

I am Meghan DeChello, a Natech Applications Engineer, and I support your product development through design transfer. I help you understand your options, navigate the risks, and make the right choices for your project. Connect with me to advance your design for manufacture.