DIAGNOSTICS EXPERTISE

Natech’s Diagnostics Contract Development and Manufacturing Helps Bring Your Life-Saving Ideas to Life

New and disruptive life-saving opportunities are rapidly occurring in the diagnostics space. These products need to launch and scale at an accelerated rate. For over two decades, Natech has brought ideas to life as the contract development and manufacturing organization for the IVD industry. Our expertise in manufacturing for lateral flow, molecular diagnostics, and microfluidics will help move your ideas from concept to commercialization.

By partnering with Natech Plastics, there is a value-added and detailed structure in place to ensure your diagnostics devices make it from the design and tooling phase and into full-scale production. Natech’s process empowers diagnostics clients to focus on their end-users, knowing their parts are being manufactured at the highest level of quality.

FROM DESIGN TO PRODUCTION, WE’RE WITH YOU

Natech supports you by being your partner during product design and design for manufacturing for IVD and life sciences devices. As an ISO 13485 Medical Molder, we understand the importance of establishing quality early in the design process.

GET EXPERT DIAGNOSTICS ADVICE

Reach out to our engineering team to get assistance on your next project. Natech engineers focus on adding value and streamlining your product development process.

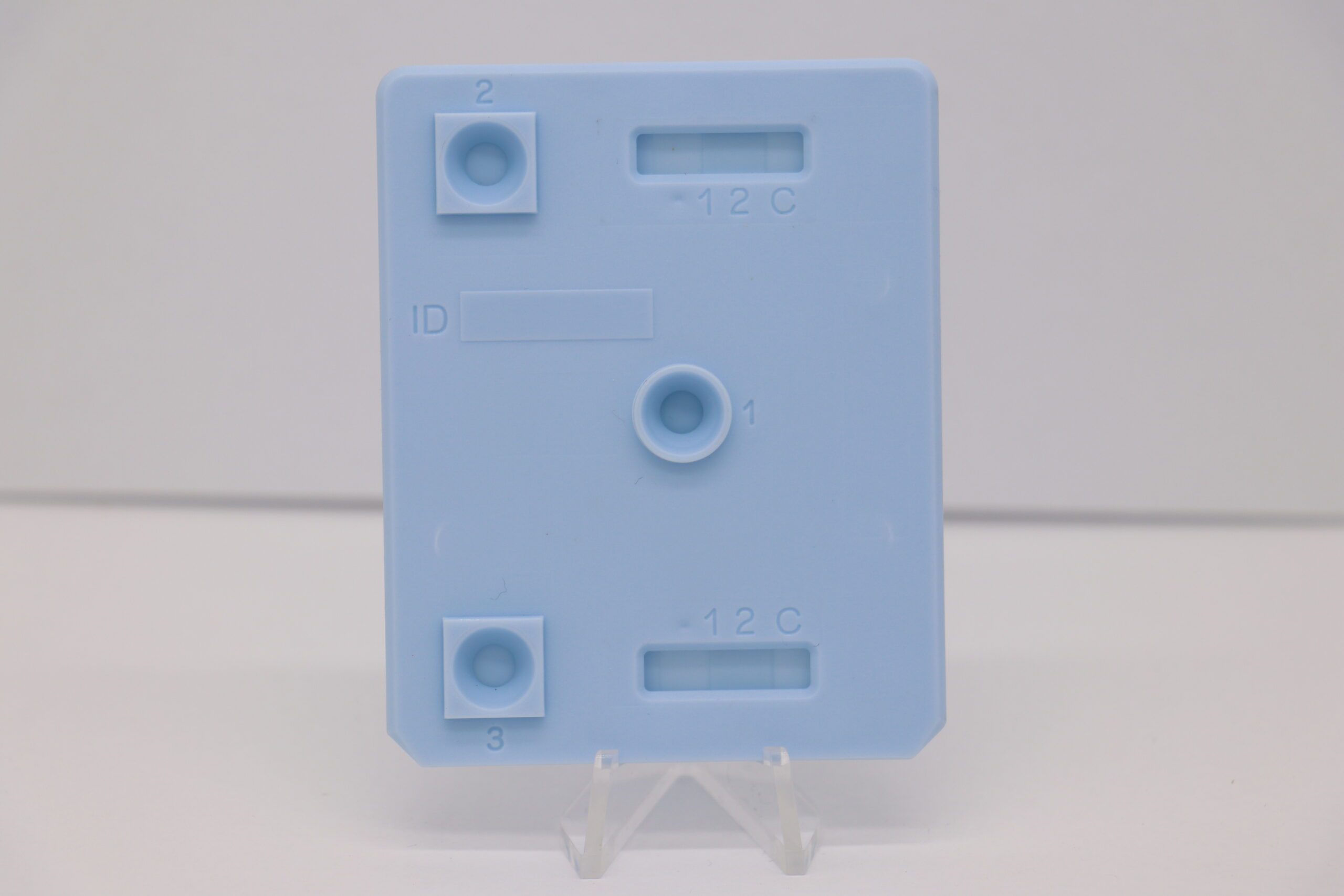

LATERAL FLOW

Moving from R&D to production for lateral flow products should be a smooth and scalable transition. Natech’s engineers design and implement processes to allow you to quickly ramp up your production.

Lateral Flow Capabilities:

- Design for Manufacturing and Assembly

- Engineered design of pins and bosses for a reliable fit

- Design of pressure points for accurate interference with lateral flow strip

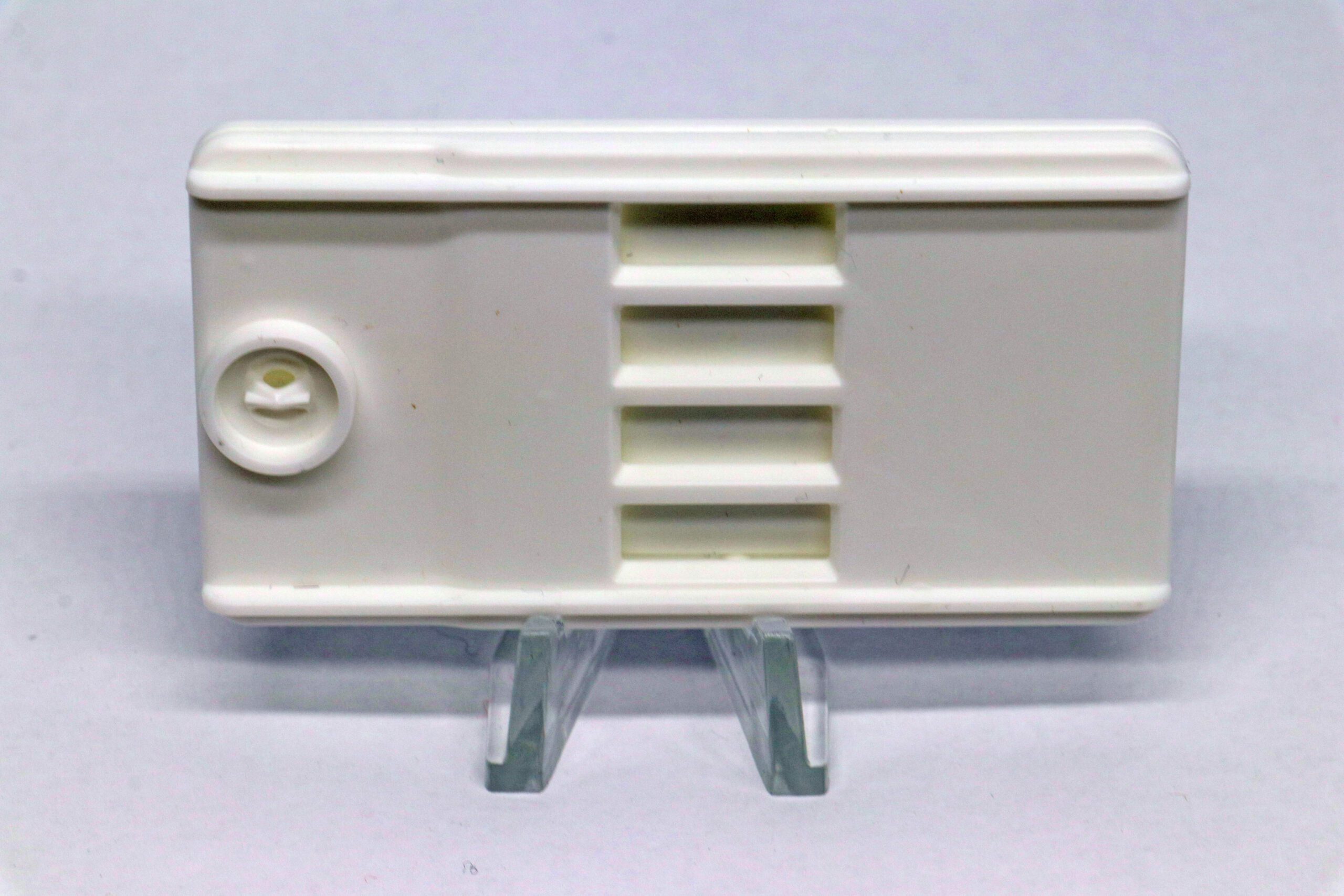

- Lateral flow product injection molding

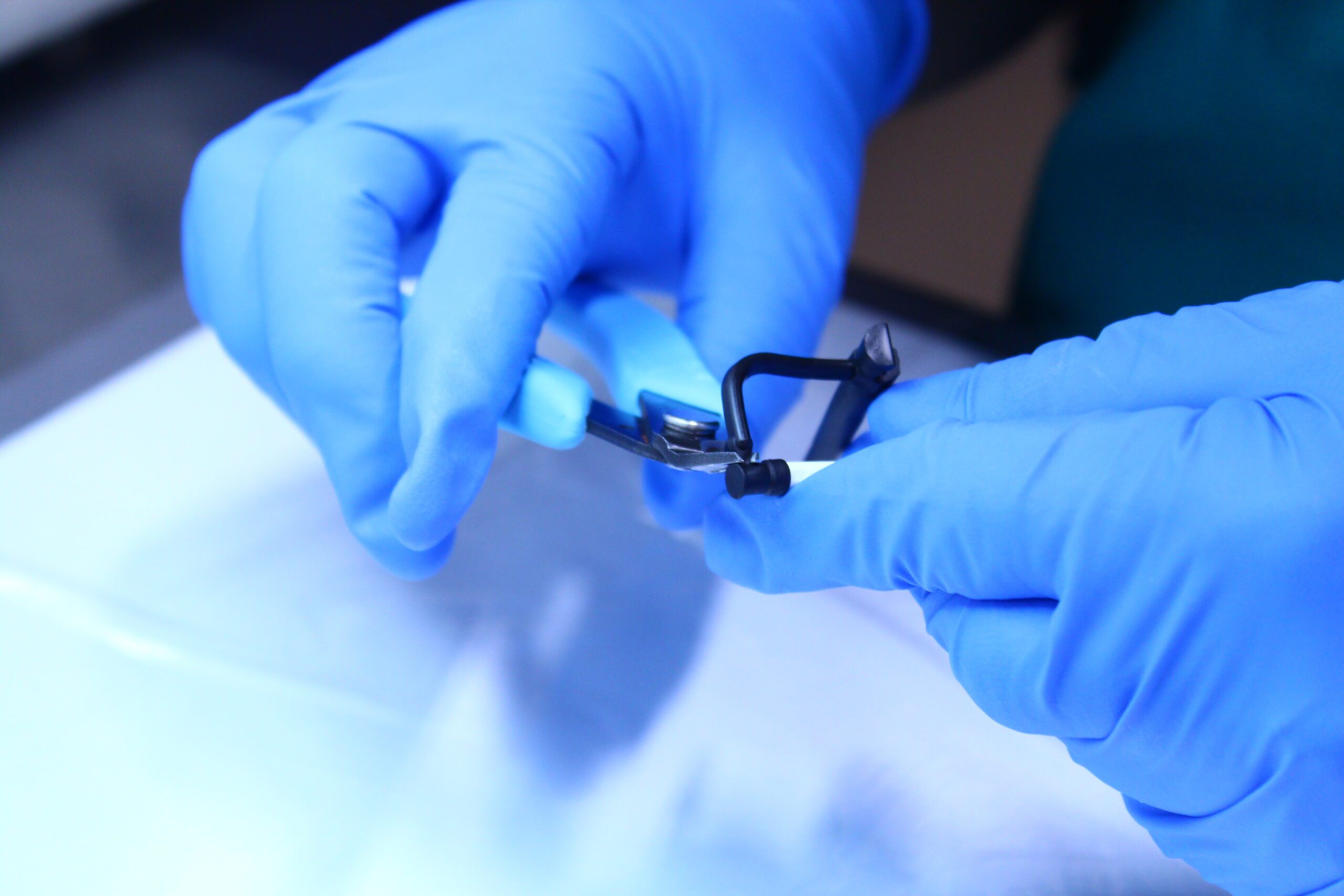

- Lateral flow cassette assembly

- Lateral flow device assembly

- Packaging and labeling

FLUIDICS & MICROFLUIDICS

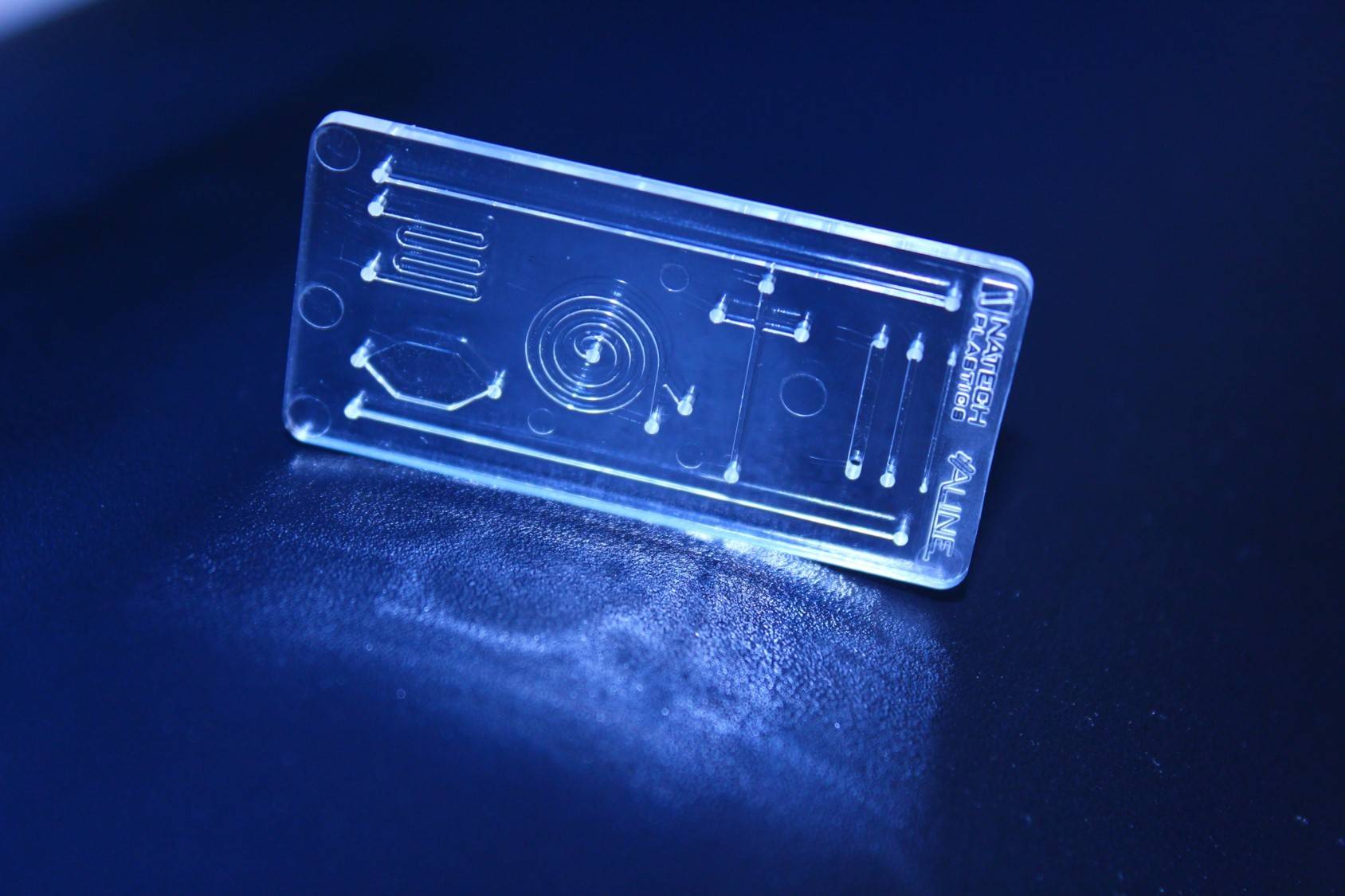

Achieve tight tolerances, precise features and smooth finishes with your fluidic and microfluidic chips.

Microfluidic Capabilities:

- Small, Precise Channels and Features

- Natech manufactures microfluidic chips with channels as small as 25μm x 25μm. Common channels range from 250μm to 500μm.

- Tight Tolerances and Complex Geometry

- Our engineers can achieve tight tolerances in the injection molding process for +/- 4μm tolerances.

- Smooth Surface Finishes

- The team at Natech can achieve an A-1 surface finish with our high-performance steel molds.

- Mastery of Materials in Microfluidics

- We have experience injection molding microfluidic chips with materials such as COC, COP, PMMA and PC.

FILLING & SEALING

After injection molding, many IVD products require filling and sealing with various liquids and reagents. Natech’s team of engineers develop customized solutions for low and high volume production.

Filling and Sealing Capabilities:

- Custom filling and sealing stations

- Automated filling processes

- Foil sealing and capping

- Filling of on-board reagents and solutions

- Custom trays and packaging

- Blister packaging

LEARN MORE

Contact Us to kick off your diagnostics device manufacture or to Request a Quote.