Application

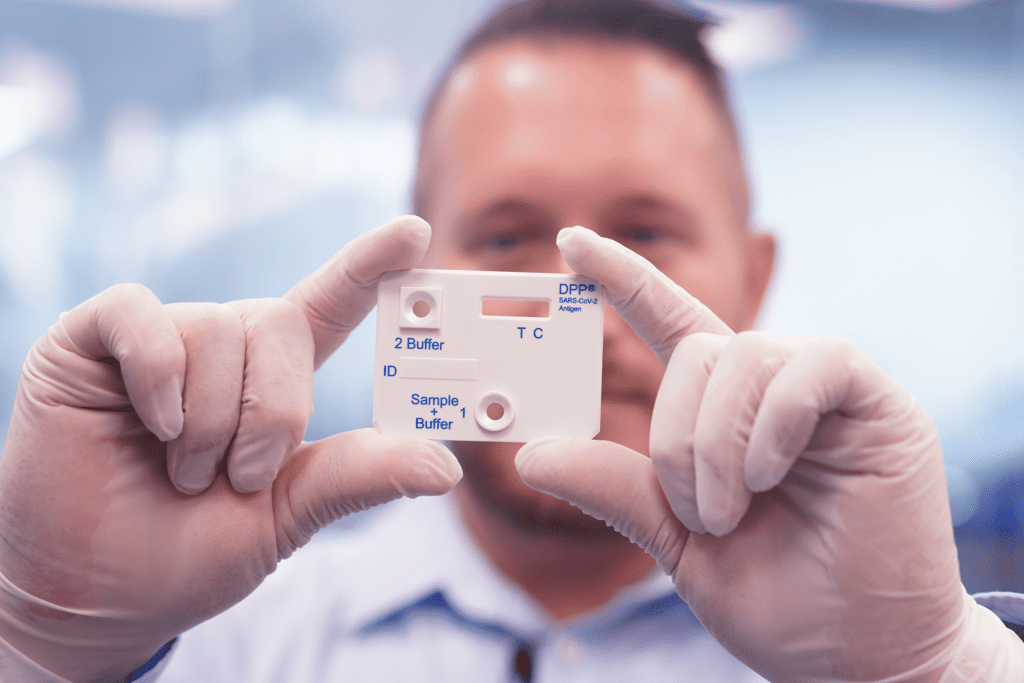

The client: A diagnostics client came to Natech to produce lateral flow cassettes.

The product: These tests would allow doctors to quickly test for diseases like Ebola, Syphilis, Zika, Dengue Fever, HIV and COVID. They help stop the spread of disease and give patients access to the medication and treatment they need.

Problem

When the COVID-19 pandemic hit, the client reached out to Natech with an urgent need for high volumes of lateral flow cassettes. People’s lives were depending on the ability to quickly and accurately test for the virus. Time was of the essence, as the client was operating in a highly competitive industry, with international competitors vying for market share. The need for speed and efficiency was matched by the need for cost-effectiveness, and any inefficiencies in design, development, and mold-making could delay production and hinder the fight against the virus. It was a challenge our team was ready to take on.

Solution

Rapid Scale Up Plan

In response to the client’s need for speed, low costs, and high volumes of lateral flow cassettes for COVID-19 testing, our team at Natech developed a comprehensive scale-up plan.

We began by assessing the client’s needs and identifying the most popular and in-demand tests to focus on. We then reduced the complexity of the initial cassette design while maintaining its functionality, which reduced costs and allowed us to receive the mold faster.

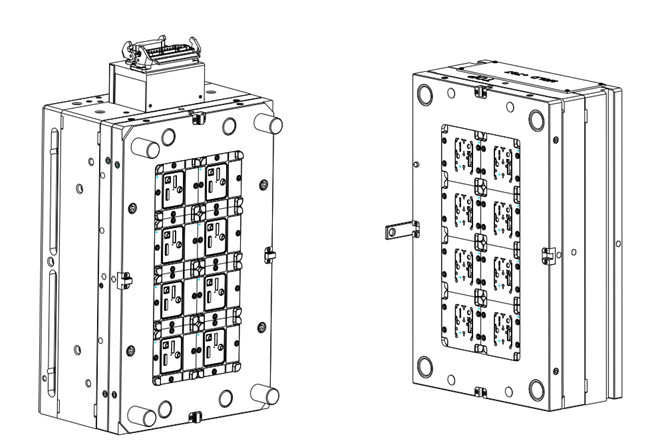

Our team quickly got to work building the tool, sampling, and testing it. Within a month, we had two four-cavity aluminum molds running production. As the demand for tests continued to grow, we scaled up production even further, building multiple four- to eight-cavity production molds to produce hundreds of thousands to millions of parts per year.

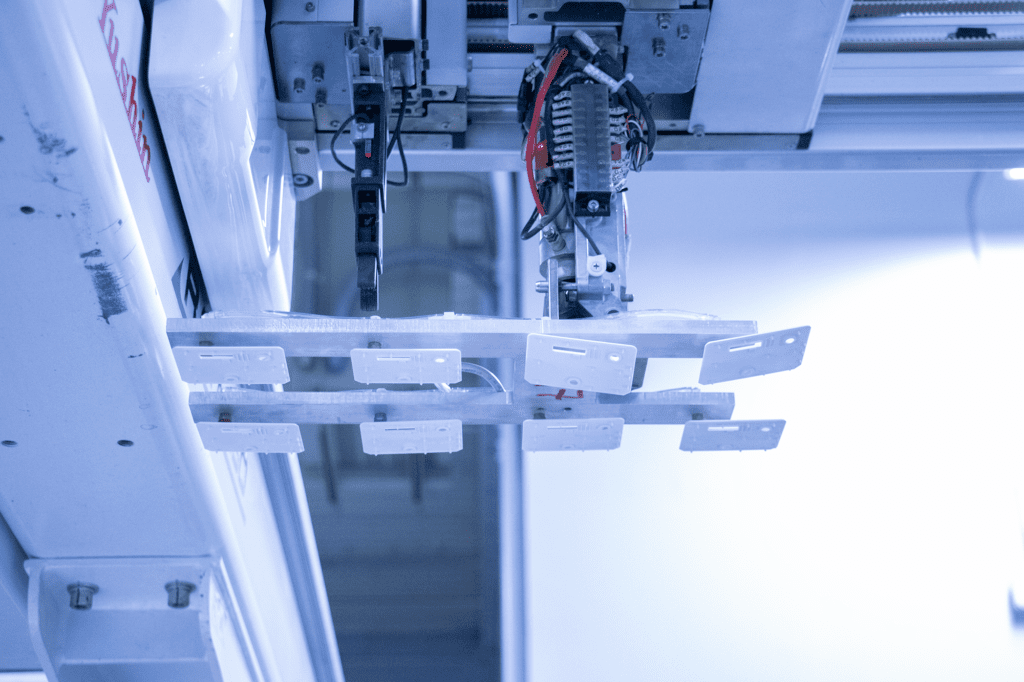

Additionally, the client required custom decorating for their product. We suggested using semi-automated and automated pad printing cells to efficiently produce high volumes of finished parts in order to meet the client’s requirement.

Results

Our focus on scaling up production allowed us to meet the client’s urgent need for high volumes of lateral flow cassettes during a critical time in the fight against COVID-19. In total, we built 30 molds and supplied 170 SKUs for this client.

With scaling up always at the forefront of our minds, we helped the client go from initial designs to commercialized products. Natech offers comprehensive solutions for companies looking to break through the diagnostics market. Our approach of reducing design complexity not only reduces costs, but also allows for fast moldmaking and a quick start to production. Our contract manufacturing services and ability to scale up production helps startups and companies meet the demands of a highly competitive market.

With Natech’s expertise in design iterations, you can be confident that your device will meet your specifications and expectations.