Filling and sealing with on-board reagents, antiseptics and buffer solutions with Natech.

New and disruptive life-saving opportunities are rapidly occurring in the diagnostics space. These products need to launch and scale at an accelerated rate. For over two decades, Natech has brought ideas to life as the contract development and manufacturing organization for the IVD industry. Filling and sealing has become integral for many diagnostics devices.

Our expertise in manufacturing for lateral flow, molecular diagnostics, and microfluidics will help move your ideas from concept to commercialization. Together, let’s bring your life-saving ideas to life and make sure great products get made.

Filling and Sealing

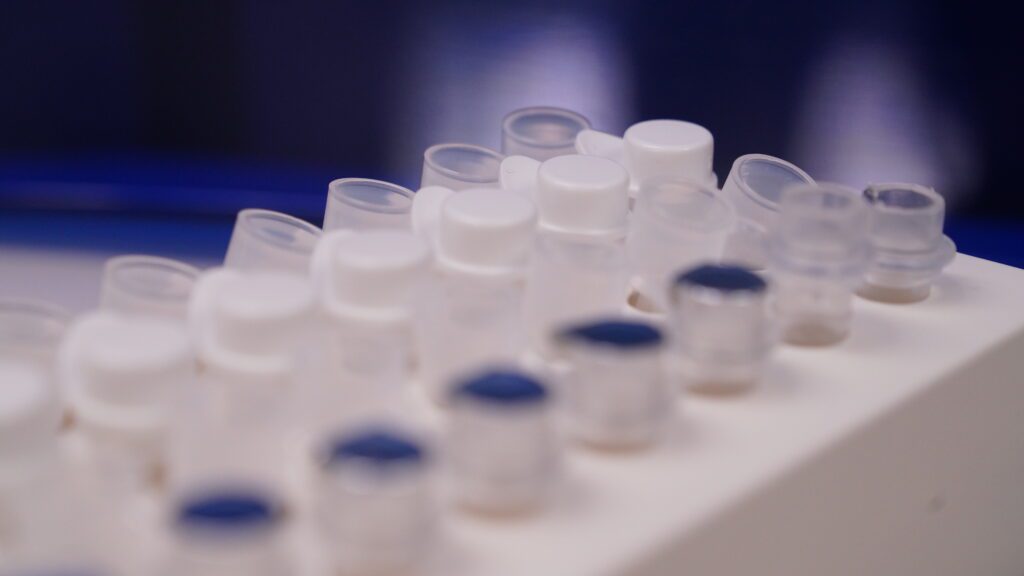

After injection molding, many IVD products require filling and sealing with various liquids and reagents.

Natech’s team of engineers develop customized solutions for low and high volume production. This includes custom stations, automated processes, custom packaging and final assembly.

Filling and Sealing Capabilities

- Custom filling and sealing stations

- Automated filling processes

- Foil sealing and capping

- Filling of on-board reagents and solutions

- Custom trays and packaging

- Blister packaging

Filling and Sealing Processes

You might need to fill and seal vials, bottles, or any container with liquid.

Natech has added filling, sealing, and capping capabilities for our clients and we have extensive experience with these processes. Our filling and sealing capabilities all include custom work cells, automated processes, foil sealing and capping, and custom trays or packaging. We can take designs to injection molding to final assembly. Our expertise in manufacturing for lateral flow and molecular diagnostics will help move your ideas from concept to commercialization.

Filled and Sealed Products

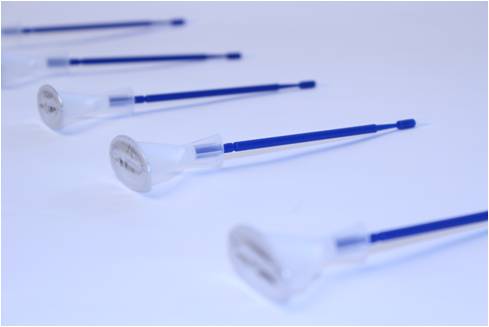

Resealable Medical Swab

Extraction Tube (Foil and Cap Seal)

Metered-Dose, Unit-Dose Tubes

Dental Whitening Snap Device

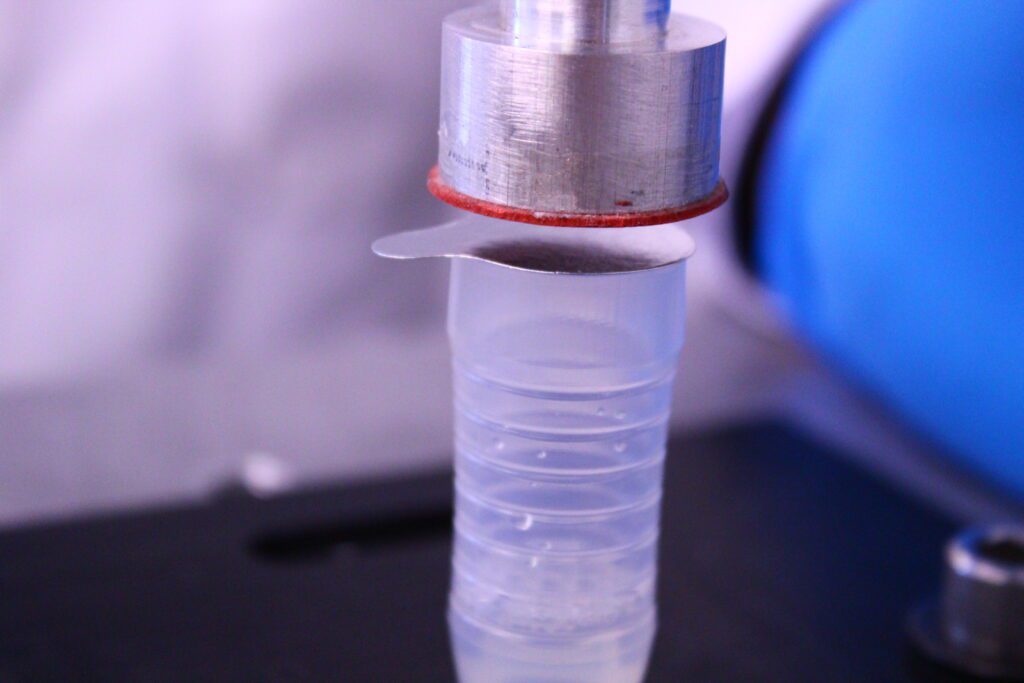

Product Highlight: Extraction Tube

Natech’s IVD clients have struggled to find a reliable supplier for extraction tubes. To overcome this challenge, Natech’s engineering and manufacturing teams developed a custom extraction tube.

Additionally, Natech manufactures, fills, seals, and packages this metered-dose extraction tube. You can customize this product to fit your diagnostics testing needs. Natech invested in new technology and equipment to support the development of this extraction tube.

Natech’s custom extraction tubes are used alongside many different rapid diagnostics tests, including COVID-19 tests.

Features and Benefits

- Raw Material Traceability

- Quality Lot Consistency

- Foil Seal and Capping Options

- Reagent and Solution Filling Options

- Permeability-Tested

- Tube Clarity

- Product Ductility

- Custom Trays and Packaging

Leak and Seal Testing

For devices that are meant to be filled and sealed, there is a risk that the liquid could leak. Depending on the type of seals in an application, the seals can be tested via weight loss evaporation testing, pull force testing, and or vacuum testing.

Example 1: Torque Testing Using a Torque Wrench

Torque is a twisting force that causes rotation. You can apply torque to a nut, bolt, screw etc. A torque wrench is a tool that can quantify the amount of torque, or twisting motion, applied. To test one of our custom products, our engineers applied torque via a torque wrench to simulate someone tightening the cap onto the container body.

Natech uses torque testing to apply torques of various measurements to quantify the most suitable torque that creates the best seal. The best seal would be measured by the least amount of liquid evaporated from the tube over time.

Example 2: Accelerated Shelf Life Test Using a Heat Chamber

Natech uses a heat chamber that heats up using forced air convection and a fan that cycles the air inside.

An “accelerated shelf life” test simulates a shelf life for a product that would take years in regular conditions, but when heated up for a shorter amount time, simulates that shelf life expectancy.

Exciting developments in the life sciences and IVD markets mean more opportunity for industry startups, innovators and disruptors. Our mission at Natech is to make sure great products get made, and we have developed solutions to help innovators launch and scale their game-changing products.