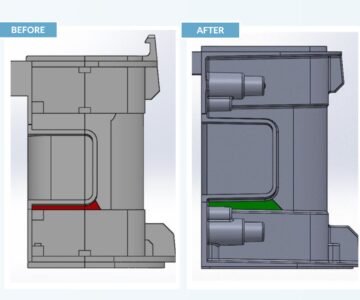

Mold Inserts – Design for Scalability

Challenge

Size and feature variations to the part would require eleven separate molds.

Size and feature variations to the part would require eleven separate molds.

Solution and Results

Integrating flexibility into the mold design helped the client avoid the costs associated with building a new mold for each variation.

Integrating flexibility into the mold design helped the client avoid the costs associated with building a new mold for each variation.